Selectiv’ Process Winery 3

Selectiv’ Process Winery

Improved Cleaning

- Major improvements have been made to the opening of machine parts to facilitate access and thus reduce washing times and water consumption.

Unmatched Quality

- Unmatched quality

- 99.8% cleanliness *

- 95% of petioles> 35 mm removed

- Whole berries

- High sorting quality for high throughputs

- Principle proved by more than 2000 users

- Quality work in manual or mechanical harvesting

Adaptable

- Range adapted to your needs

- Roller spacing is adaptable to the harvest (depending on the size of the berries)

- Range adapted to each cellar size

- All sorting technologies on one machine

Reduce Sorting Costs

- Reduction of sorting costs

- Separate small seeds/raisins from sorted fruit

- Reduced labor costs

- Up to 25% savings in the overall cost of ginning and sorting

Improved washing

- Major improvements have been made to the opening of the machine elements in order to facilitate access and thus reduce washing times and water consumption.

Simple and intuitive adjustment

- The control panel is close to the work area, so the operator can see the result and optimize the settings.

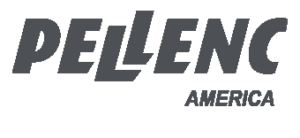

Selectiv’ Process

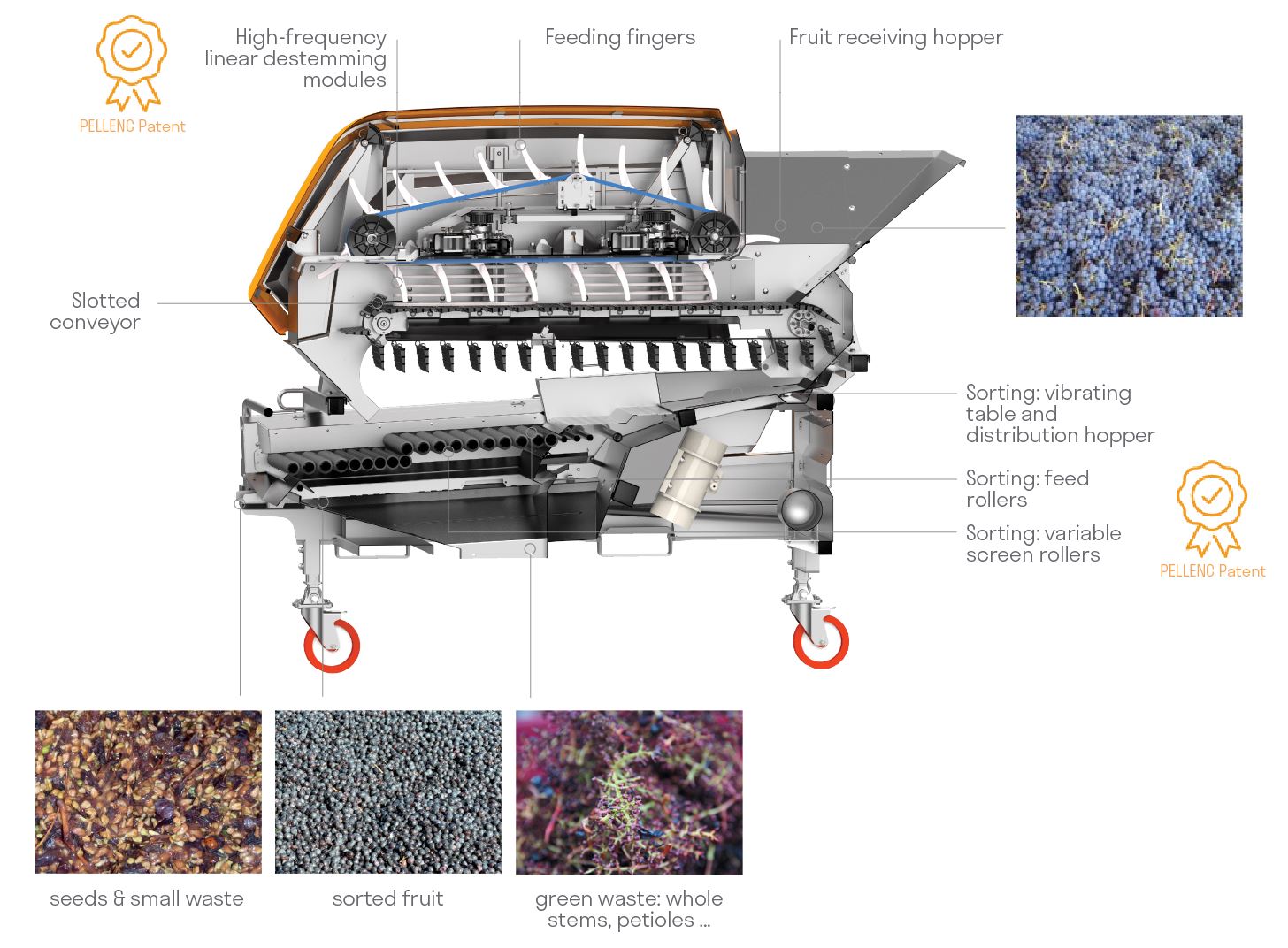

- Gentle separation of the berries from the stems: intact berries, whole stems.

- Feeding the sorting table: the destemmed berries pass through the slatted conveyor, avoiding maceration.

Automatic Chain Tensioning

- The vibrating draining and distribution hopper prepares the harvest for sorting: elimination of juice and small waste (seeds, rejected berries, small insects, etc.)

- The PELLENC double-level roller sorting table: reorients the petioles (full notched feed rollers), sorts the harvest and eliminates green waste: stems, leaves, petioles, branches, foreign bodies … (screen rollers topped with spikes)

- This sorting is optimized with simple adjustment of sorting roller gap to match the berry size.

Technical characteristics

| SELECTIV’ WINERY – S | SELECTIV’ WINERY 3 – M | SELECTIV’ WINERY 3 – L | |

| Flow (manual harvest) * | up to 4 t/h | 3 to 10 t/h | 7 to 20 t/h |

| Flow (mechanical harvest) * | – | 4 to 12 t/h | 10 to 25 t/h |

| Length (overall in mm) | 2205 mm / 86.8 in | 2,600 ( 102.4 in ) | 2,820 ( 111 in ) |

| Width (overall in mm) | 1175 mm / 46.25 in | 1,575 ( 62 in ) | 1,740 ( 68.5 in ) |

| Total height (min-max in mm) | 1730-2270 mm (68.1 – 109 in) | 2,020-2,570 ( 79.5 in to 101.1 in ) | 2,090-2,640 ( 82.3 in – 103.93 in ) |

| Machine weight (all options in kg) | 600 kg (323 lbs) | 950 ( 2094 lbs ) | 1300 ( 2866 lbs ) |

| Rated power (kW) | 4.8 | 4.3 | 6.9 |

| Destemming frequency | 400 to 860 movements / min | 400 to 860 movements / min | 400 to 860 movements / min |

| Manufacturing material | Inox 304 L | Inox 304 L | Inox 304 L |

| Feed hopper (in mm) | 1,040 x 800 (40.95 in x 31.5 in ) | 1,410 x 800 ( 55.5 in to 31.5 in ) | |

| Number of destemming modules | 1 | 2 | 4 |

| Vibrating table and distribution table | N/A | • | • |

| Height-adjustable castor feet 500-1050 mm | option | option | option |

| Caster feet 1050-1300 mm | option | option | n/a |

| Support frame above Integral’Vision | option | option | n/a |

| Seed / juice separation | • | option | option |

| Remote on / off box | option | option | option |