The Grapes’Line tow behind harvester includes all the latest PELLENC innovations. It has a harvesting capacity of 3,600 litres (950gal) – the same as that of a self-propelled harvester – while remaining less costly. Highly efficient, it also provides wine-growing professionals with an unrivalled work quality thanks to its easy handling and user-friendly nature.

Efficient

- Harvesting capacity identical to a self-propelled harvester

- 50% cheaper than a self-propelled machine

- ECO POWER fuel management: optimised power take-off according to the machine’s hydraulic requirements

- Total collector-bin capacity of up to 3,600 litres (950gal)

Excellent work quality

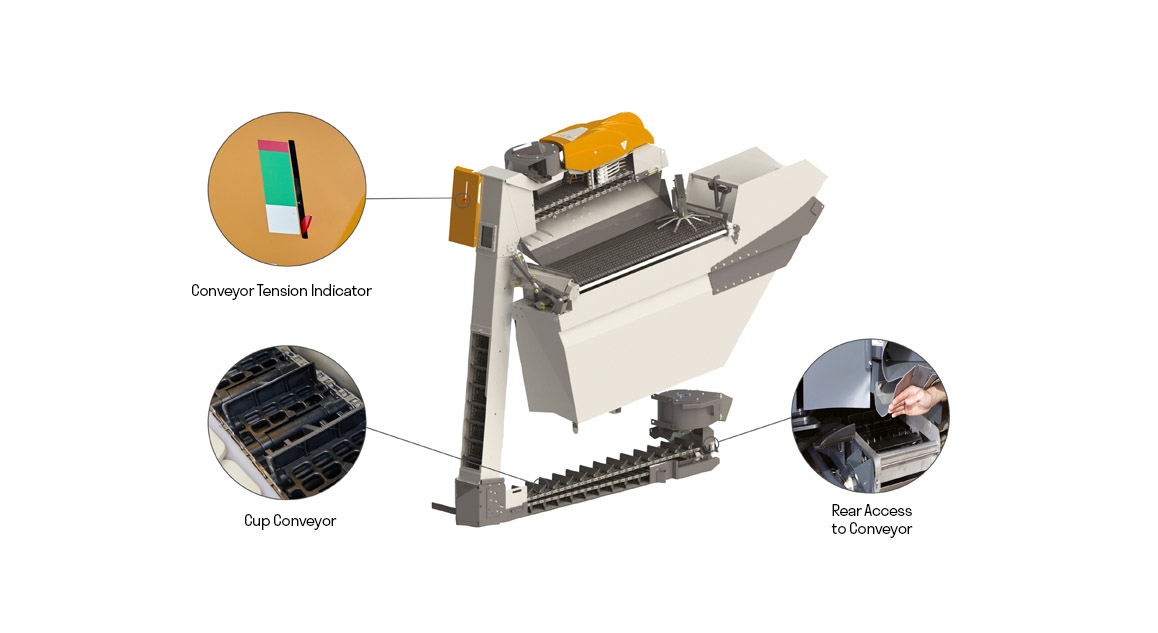

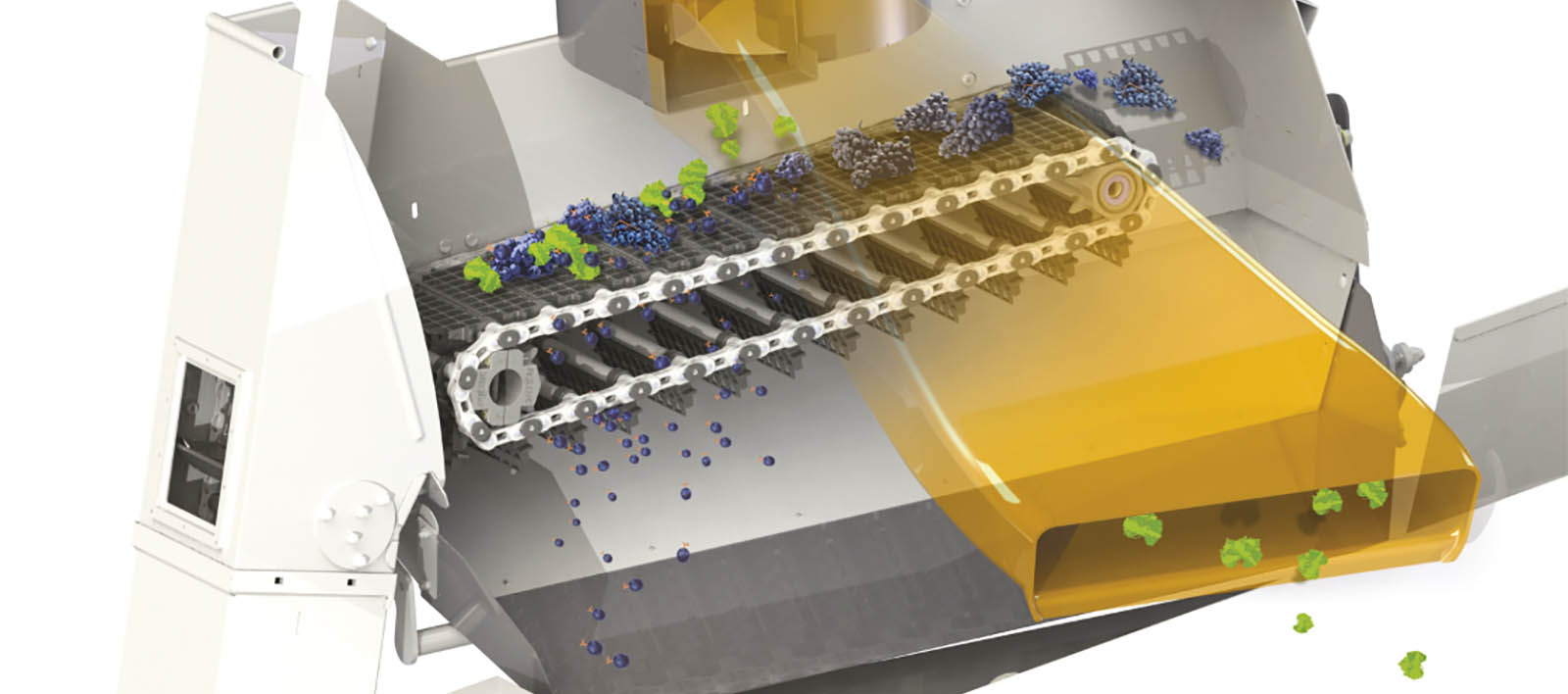

- Flexible Sorter Conveyor: up to 5% more harvest in your collector bins!

- New tortoiseshell shape: optimal sealing

- New generation harvesting arm

- SELECTIV PROCESS: 99.82% clean harvest

Ergonomic

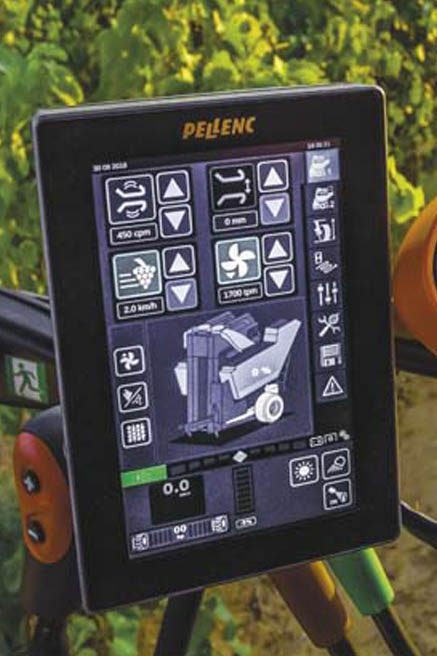

- 7-inch touchscreen

- Safe washing platform

- Remote washing commands

- Centralized greasing

Easy to handle

- Auto-guidance in the row

- Semi-automatic tilt correction

- Optimized turnaround in headlands with the wide-angle drawbar

- AUTO TORQUE drive: machine-independent on slopes and in headlands