Get the best out of your fruit!

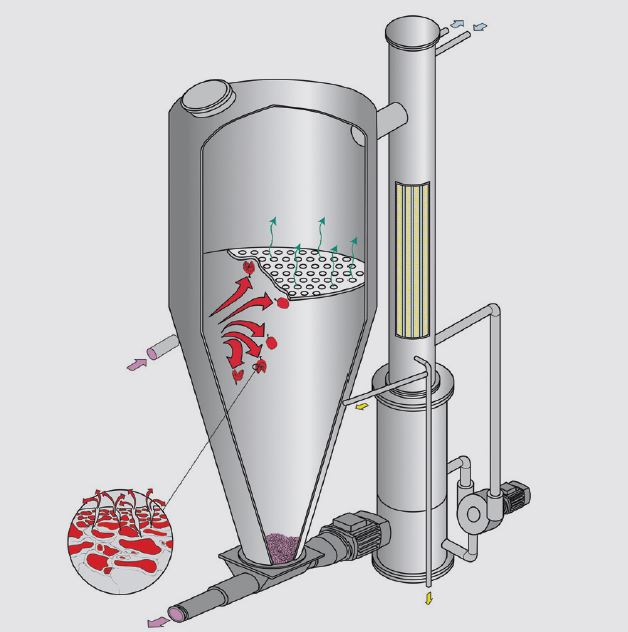

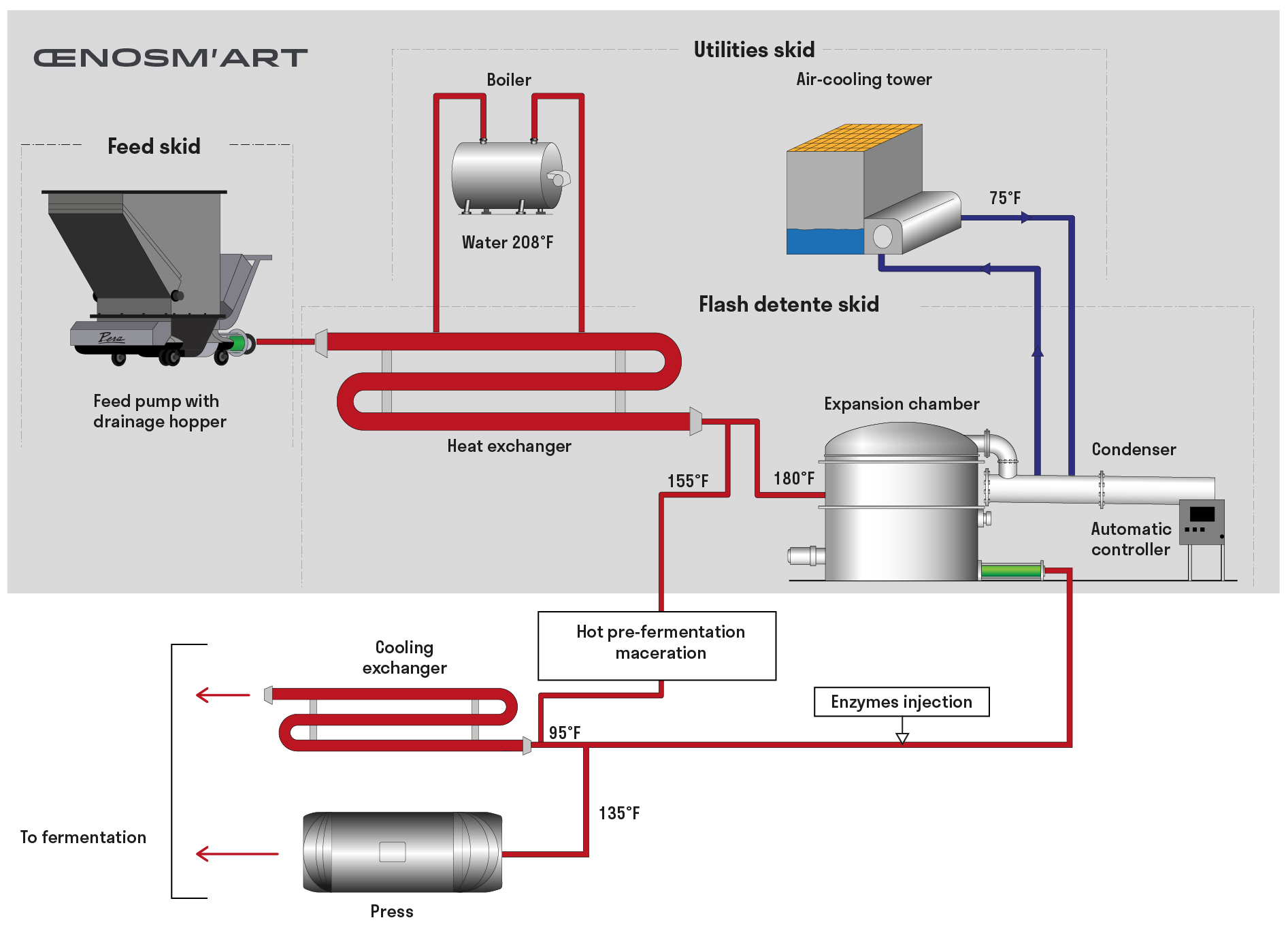

This innovative thermovinification process significantly improves the quality of the wines and adapts the type of wine to consumer demand. OEnoSm’art has been developed to meet the needs of users with its versatility.

Quality

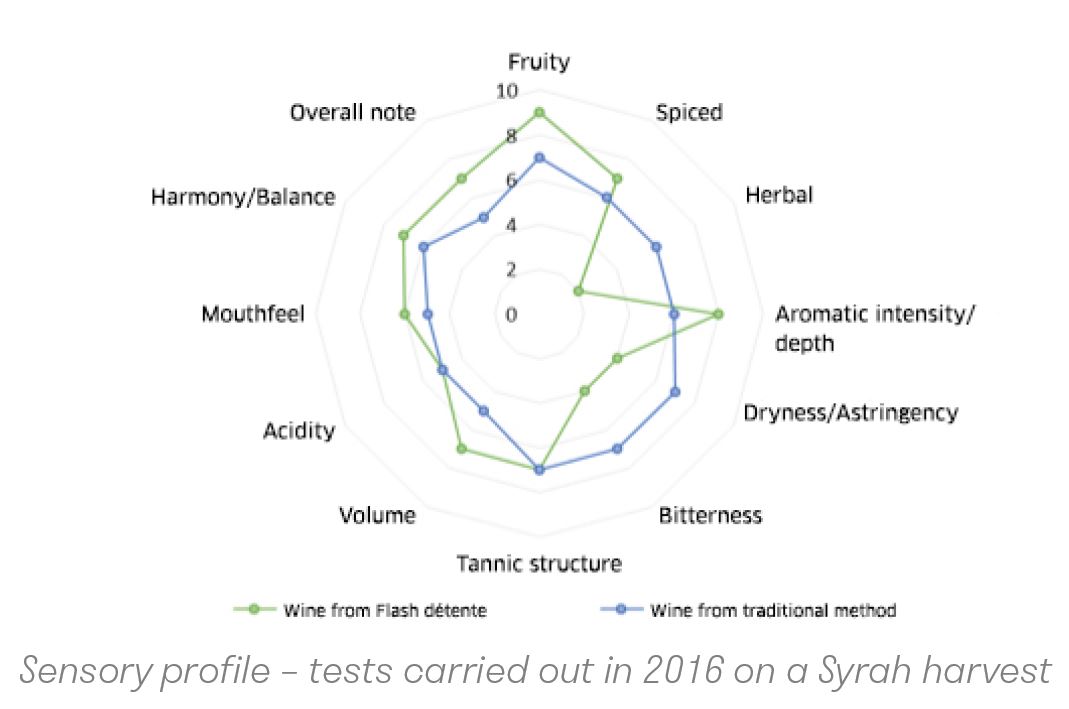

- Rounder, fuller, fruitier wines.

- Stable color and aromas.

- Denatures harmful enzymes (laccase, polyphenol and oxidase).

- The full potential of the grapes is revealed.

- Better incorporated yeasts: optimized fermentation kinetics

Performance

- Non-stop operation possible.

- Continuous process up to alcoholic fermentation.

- Improved cellar capacities to produce new styles of wine or juice.

- Optimized cellar with more opportunities for the vinification team.

- Fermentation capacity increased by 25% for the same energy input.

- In-line enzyme injection at outlet from vacuum chamber, for increased efficiency.

Cost-Effectiveness

- Fewer refits, labor saving.

- The entire volume of the tank is used.

- Better temperature control during fermentation.

- Fermentation volumes up 25% with the same amount of energy.

- Easier to empty the tank (if vinification in liquid phase).

- Multifunction: either traditional thermovinification or Flash Detente

- Recover value from spoiled or under-ripe grapes

- Wine profiles adapted to market demand

Ease of Use

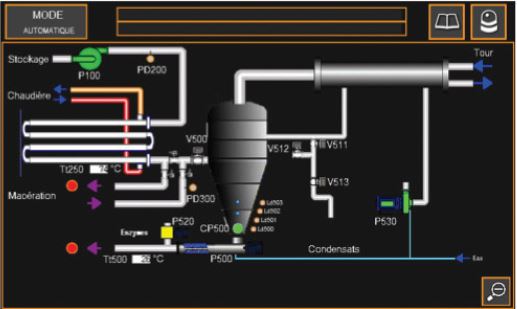

- Programmable logic controller.

- Simple and intuitive touchscreen interface.