Quality of manual work, simple and fast.

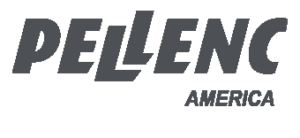

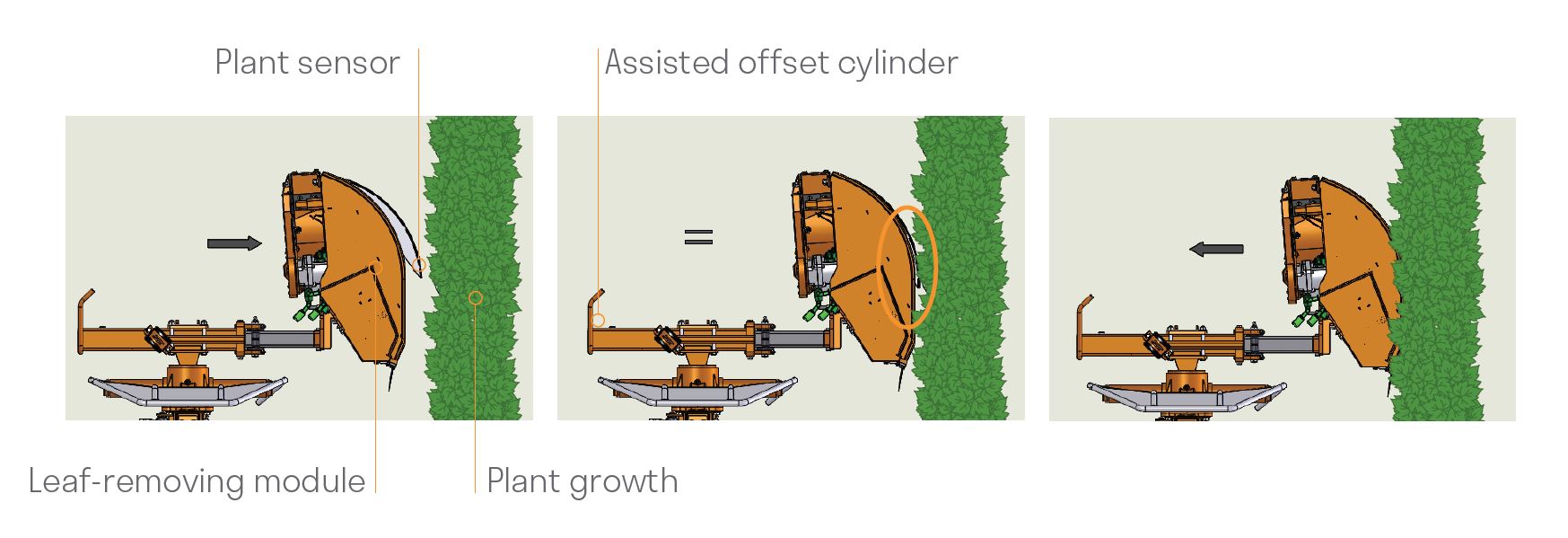

The new leaf remover suits most vineyards and the leaf removal is uniform as if performed by hand. The simple design ensures quick and easy control. The canopy is tracked by a sensor, which automatically manages the tool pressure on the trellising in real time—with no damage to the berries! Adjustments to the amount of leaf being removed is simply adjusted by the turn of a knob inside the cab!

The Pellenc Soft-Touch Vineyard Leaf remover is used to effectively and gently pull leaves from the canopy by using the Soft-Touch sensor to automatically manage leaf removal intensity (adjusted with a single knob the cab). Vineyard leaf removal with the Soft-Touch leaf puller provides the same quality as leaf-removal by hand. Available in a half-row reversible model, or a full row model, the Pellenc Soft-touch leaf remover is an excellent tool to mechanize your vineyard management. Watch the video below to see the leaf remover in action and see the difference yourself!

- High ground speed of up to 2.5 mph.

- Available in a 1/2 row, 1 row, or 2×1/2 row version.

- Suits all vineyards.

- Reduced maintenance cost.

- Low fuel consumption, with reduced power requirements.