Harvest Non-Stop!

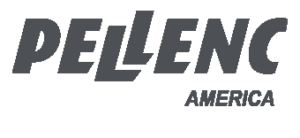

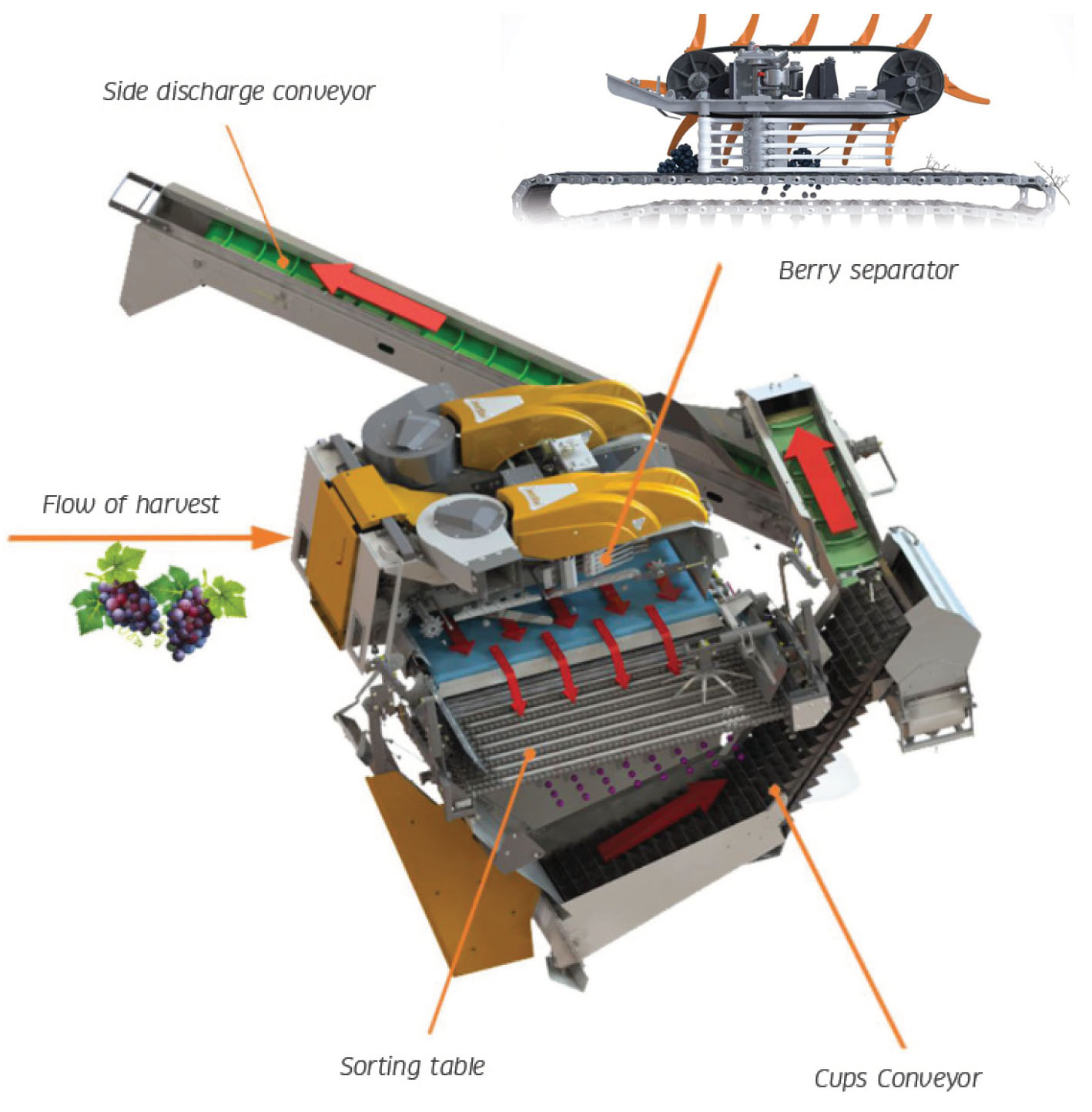

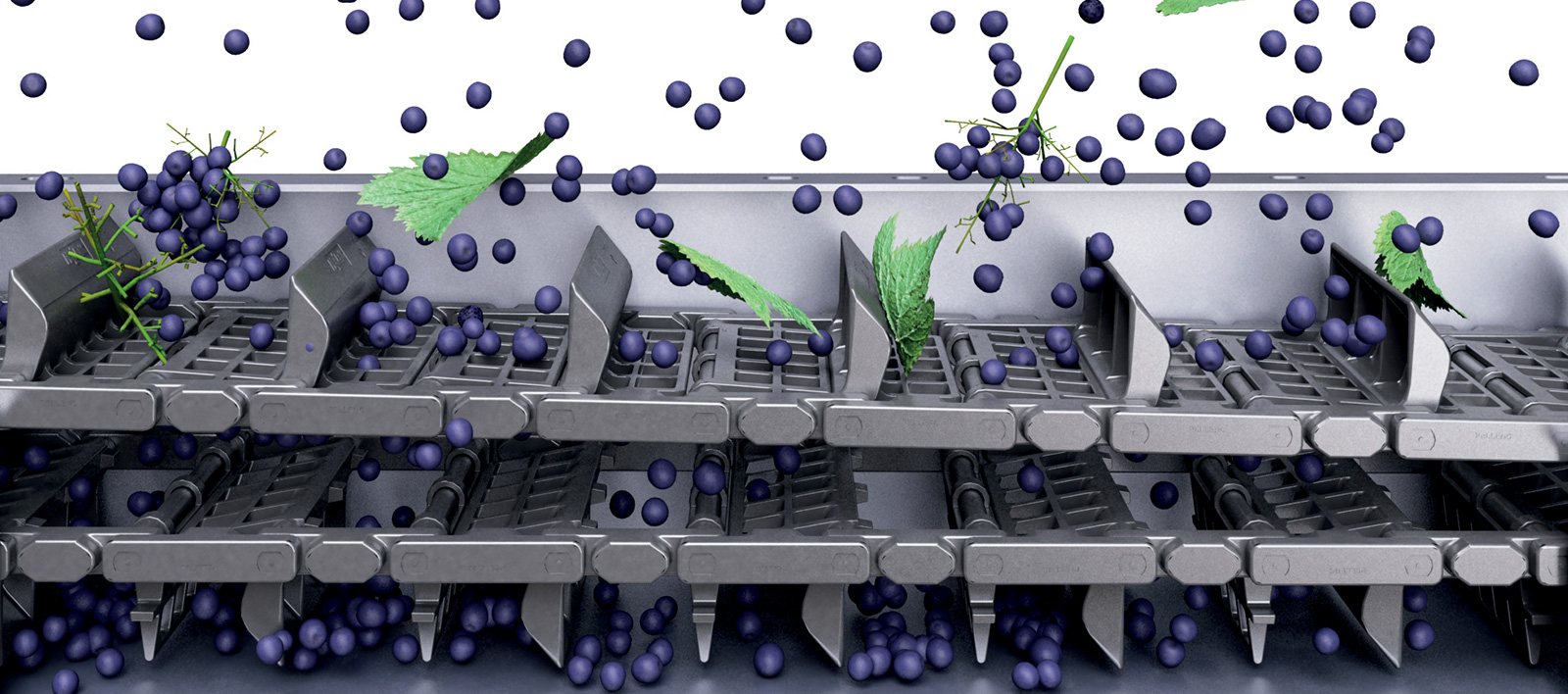

XLE-SP2 Optimum harvesting head comes with a side discharge arm and standard with Selectiv’ Process 2 on board!

The XLE allows you to harvest directly to gondolas, valley or macro bins by using the side discharge conveyor for long rows. The perfect solution for low and high yield vineyards.

CONTINUOUS HARVEST

For best-in-class working efficiency, the XLE includes a continuous harvest bin that allows you to store up to 0.8 ton when changing out gondolas and speeding up headland turns.

Harvest non-stop throughout the day or night to instantly increase your efficiency.

With a simple click, the berries are redirected from the bin to the discharge conveyor.