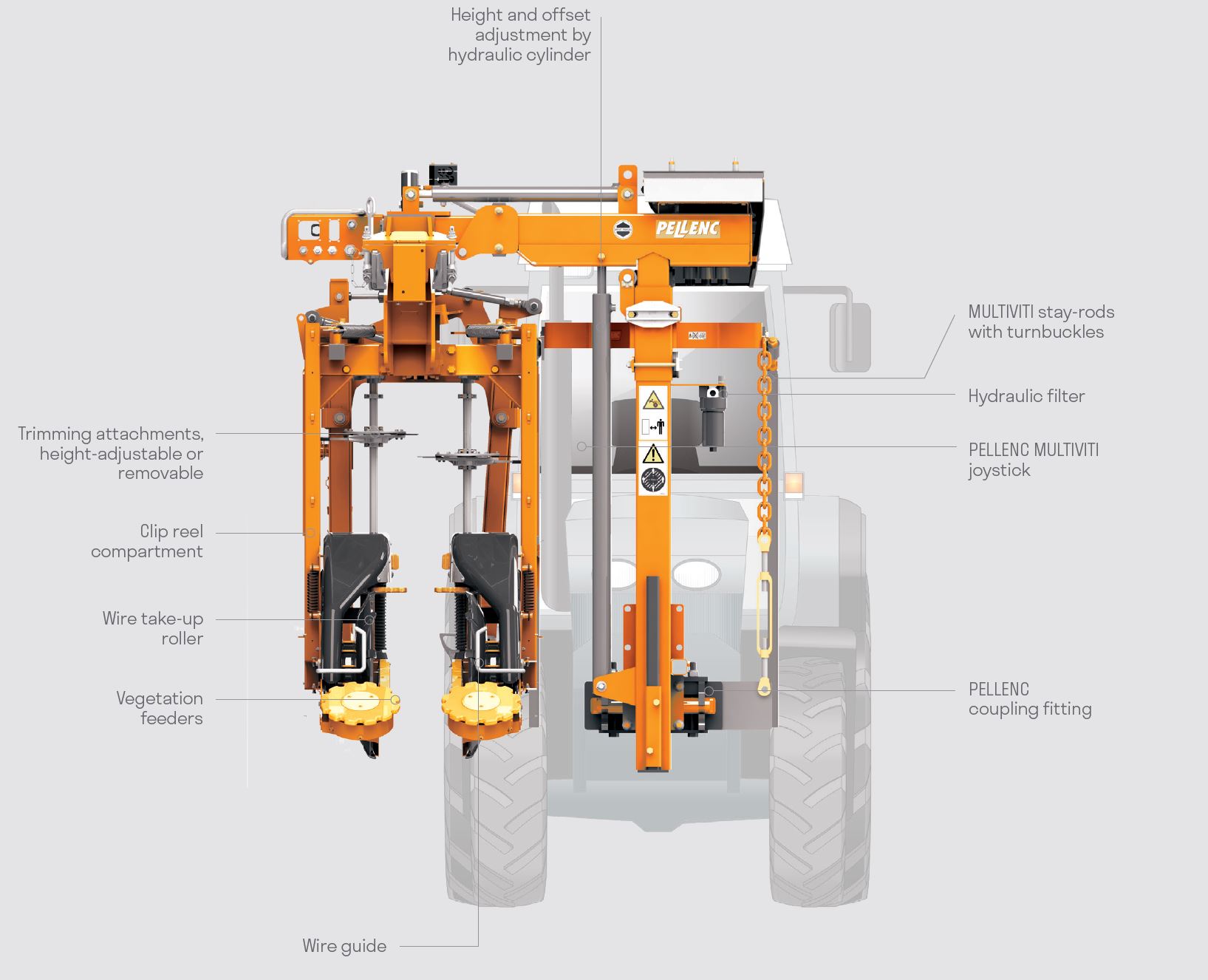

Lift, attach and trim all at once!

Perform three operations in one run, with a single tool — this is made possible by the PELLENC trellising machine! Your vines have a uniform canopy, so grape clusters are better exposed to spray treatments. Lifting the leaves improves photosynthesis, ensuring optimal maturity of the berries.