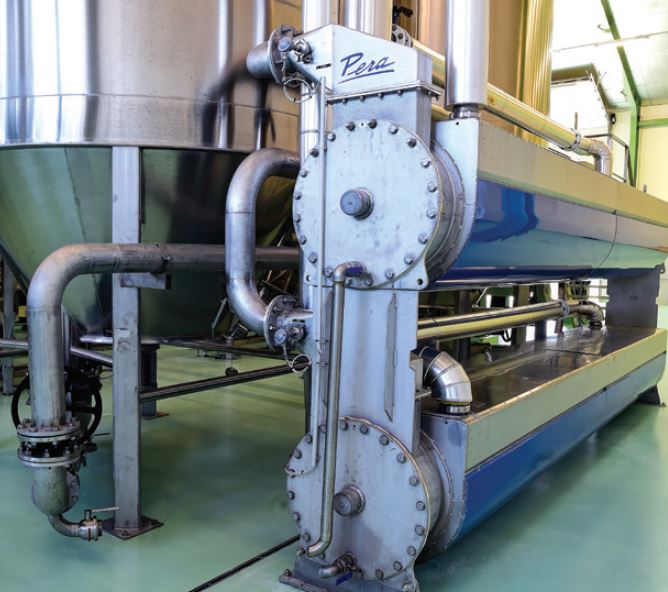

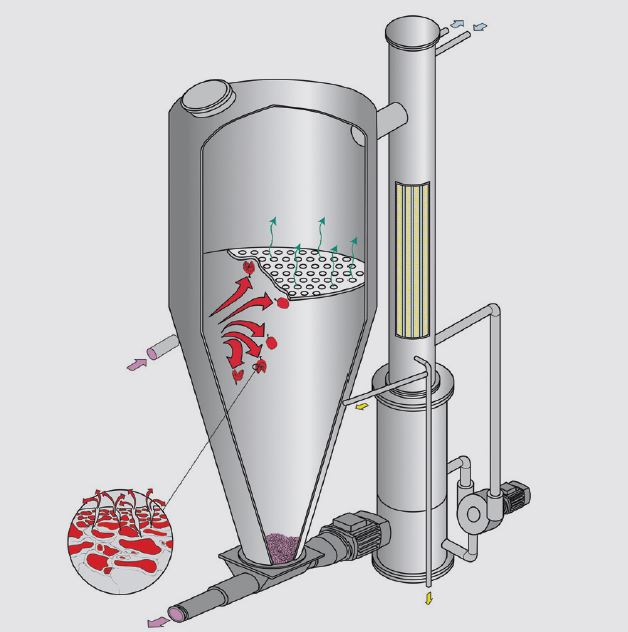

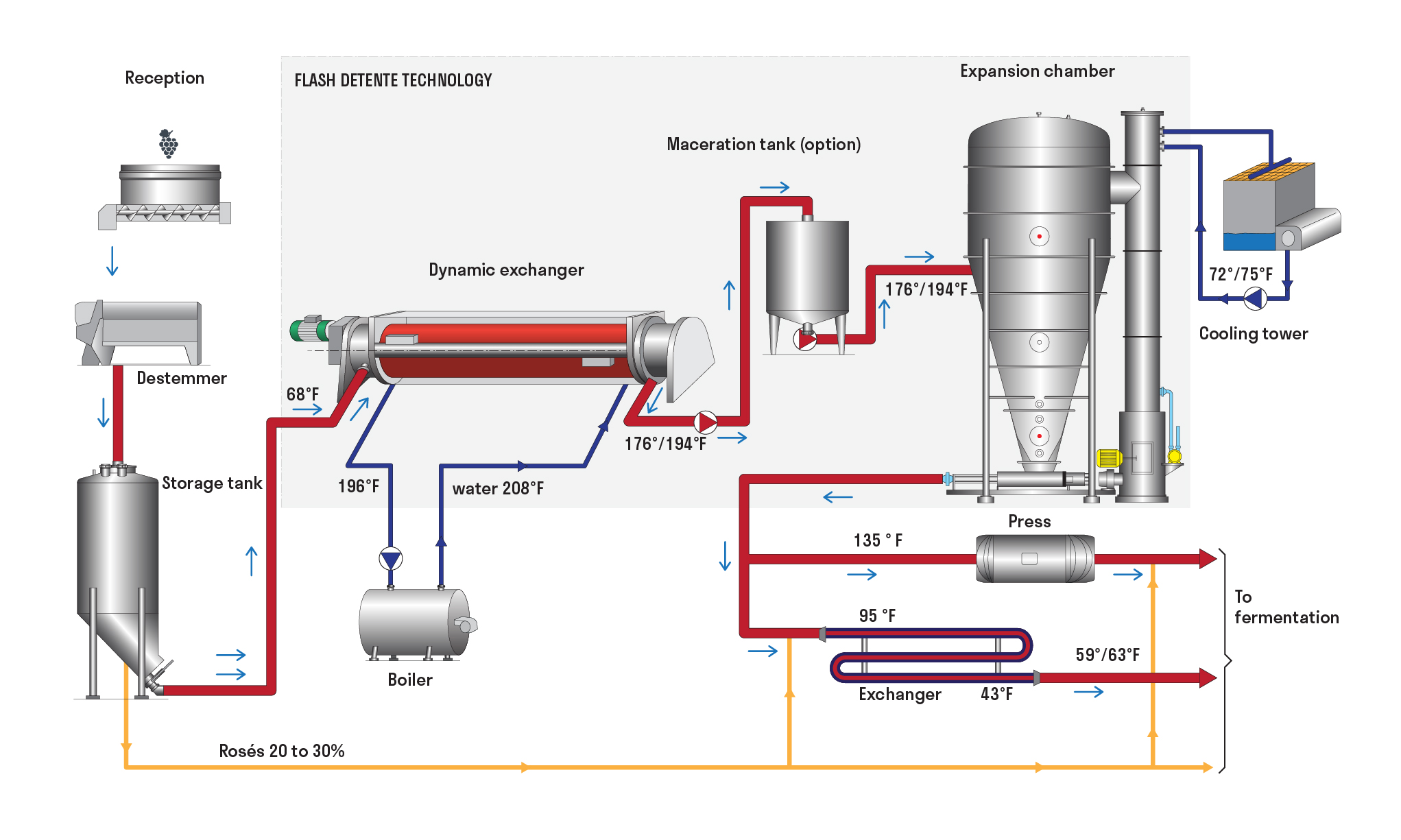

This innovative thermovinification process significantly improves the quality of the wines and adapts the type of wine to consumer requests.

Quality

- Rounder, fuller, fruitier wines.

- Stable color and aromas.

- Denatures harmful enzymes (laccase, polyphenol and oxidase).

- The full potential of the grapes is revealed.

- Better incorporated yeasts: optimized fermentation kinetics

Performance

- Non-stop operation possible.

- Continuous process up to alcoholic fermentation.

- Reduced heating costs thanks to greater flexibility with dates of harvesting.

- Improved cellar capacities to produce new styles of wine or juice.

- Optimized cellar with more opportunities for the vinification team.

- Fermentation capacity increased by 25% for the same energy input.

Cost-Effectiveness

- Fewer refits, labor saving.

- The entire volume of the tank is used.

- Better temperature control during fermentation.

- Fermentation volumes up 25% with the same amount of energy.

- Easier to empty the tank (if vinification in liquid phase).

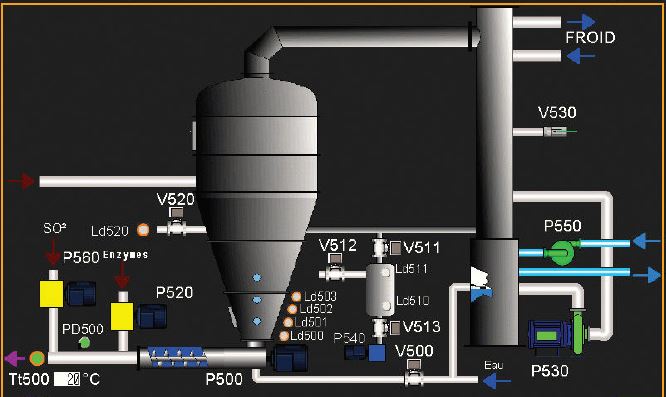

Ease of Use

- Programmable logic controller.

- Simple and intuitive touchscreen interface.