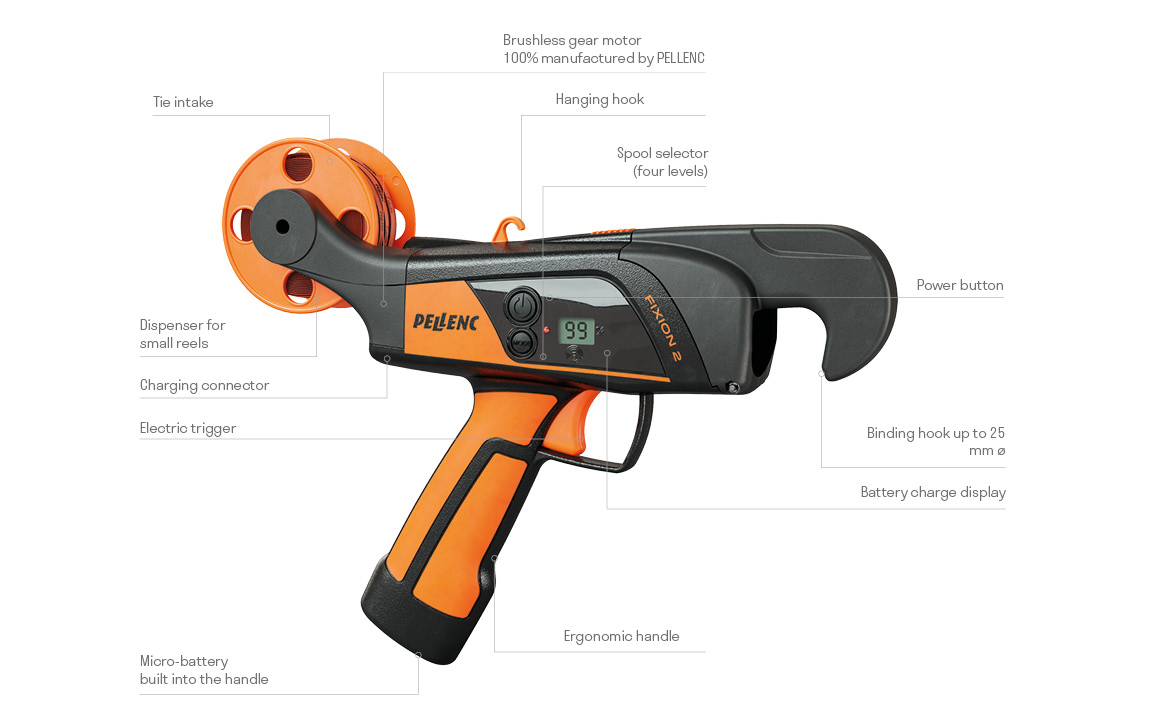

Fixion 2 Tying Machine

Attached to your freedom

One tool, two uses

200m spool on belt

Up to 1500 ties per spool

Small spool on tool

Up to 450 ties per spool

| REEL FEATURE | Large band | Small band |

|---|---|---|

| Maximum tying diameter – in | 1 in | 1 in |

| Length of the reel – (ft) | 650 | 200 |

| Ties per tie band – (approximate) | 1,500 | 450 |

| Battery life: Ties per charging cycle | Up to 15,000 | Up to 15,000 |

The Pellenc advantages

Each tie is tailored to suit the environmental conditions of the vine, the weight of the plant being tied and the time frame.

Standard tie

- Breaks down after 10 to 12 months of use according to climatic conditions, load, and quality of the trellising wire.

- .44 mm steel wire

- Average tie strength = 31 lb*

Belt spools – Ref.: 3057047

Tool spools – Ref.: 3057203

Stainless steel tie

- Slow disintegration. Use for cordon system vines and the installation of irrigation pipes.

- .44 mm stainless steel wire

- Average tie strength = 31 lb*

Belt spool – Ref.: 3057053

Tool spool – Ref.: 3057228

Paper tie

- Breaks down after 6 to 9 months depending on use. The paper retains moisture, which is conducive to breakdown of the tie.

- .44 mm steel wire

- Average tie strength = 31 lb*

Belt spool – Ref.: 3057049

Tool spool – Ref.: 3057204

Bio tie

- Breaks down after after 7 to 10 months.

Envelope composed of paper + corn starch-derived PLA (polylactic acid) - .44 mm steel wire

- Average tie strength = 31 lb*

Belt spool – Ref.: 3057273

Tool spool – Ref.: 3057274

Technical characteristics

| |

| FIXION 2 | |

|---|---|

| Weight of tying machine alone | 1.75 lbs w/integrated battery |

| Noise level (LpA)* – dB(A)) | ≤ 70 |

| Guaranteed sound level (LWA)* – dB(A) | ≤ 81 |

| Vibration level (Ah)** – m/s² | ≤ 2,5 |

| Compatibility of PELLENC ties | • |

* Values of acoustic measures according to the Directive EN 60745-1: 2009 + A11: 2010 – uncertainty according to ISO4871 = 3dB

** Vibration emission values according to EN60745-1: 2009 + A11: 2010 – uncertainty = 1.5m/s²

*** For information: the times were observed in actual working time, without taking breaks into consideration. Battery life is influenced by the nature of the work.