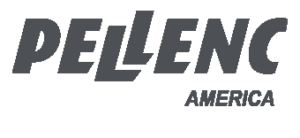

The new Smart Press range of pneumatic presses meets the needs of the most demanding winemakers. These presses are equipped with the latest innovations. The Fast Press drainage grids and the smart pressing system allow optimal use of the press to extract high quality juices. The Smart Press range of pneumatic presses, from 20 to 150 hl, with open or closed cage, meets the needs of all types of cellar.

Smart Press

COMFORT

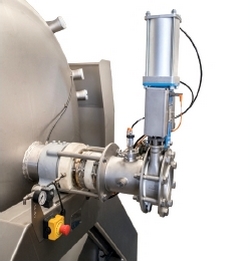

- New Touch Press color touch screen – ergonomic and intuitive

- Easy Press 2 Smart management of pressing cycles

- The press is quick and easy to wash thanks to the Fast Press* trays (15 to 30’)

- Easier to use

- Less handling by the operator

- Pomace is emptied completely and quickly

* depending on the model, type and condition of the grapes, and filling time

PERFORMANCE

- Full range adapted to all cellars

- Complete drainage cap for thorough cleaning of the press

- Robust, reliable design

- Juices run off faster:

larger drainage surface (30-140% larger)* - Improved filling capacity:

faster runoff (15-25% faster)* - Shorter pressing time

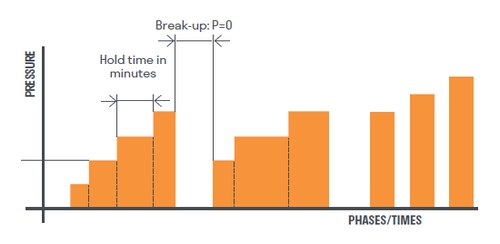

TWO MODES OF PROGRAMMING AVAILABLE

Customization

- Programming of the different pressing phases by the operator

- pressure, maintenance times, number of breaking-up cycles

- 20 programs with 99 possible programming lines

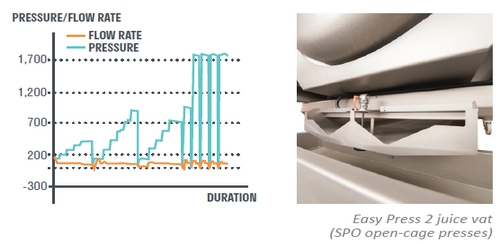

Smart

- The computer manages the pressing cycles according to the juice flow and the end of the cycles depending on the desired degree of dryness

- Pressing time and number of breaking up cycles optimized

- Better quality of the extracted juices

- Pressing stops when the press cake reaches a certain dryness

- 5 predefined types of grapes: destemmed grapes, whole clusters, fermented pomace, shot grapes, end of maceration

OPTIMIZED DESIGN FOR QUICK, EASY CLEANING:

The design is optimized for easier washing of the press:

- The new Fast Press drainage grids and the emptying coil gather the pomace towards the chosen door, so it can be removed entirely.

- The fast grid opening system makes it easier to thoroughly wash the vat. Daily washing is faster: 30 minutes on average.

- No more inaccessible corners, the vat is cleaned perfectly

OPTIMIZED DESIGN FOR QUICK, EASY CLEANING:

- Increased drainage surface: up to 360% more*

- Greater filling capacity: up to 30% more*

- Faster pressing: up to one hour less*

Pera-Pellenc R&D engineers have conceived simple, efficient systems which improve Smart Press pressing efficiency. There are significant improvements: better filling capacity, improved drainage, better pressing time, easy to use.

SPC – Closed Cage Presses

| Capacity (hl) | SPC 20 | SPC 30 | SPC 40 | SPC 50 | SPC 80 |

|---|---|---|---|---|---|

| Min quantity | 0 Kg | 0 Kg | 0 Kg | 0 Kg | 0 Kg |

| Door – 1 Manual | • | • | ─ | ─ | ─ |

| Door – 1 Motorized | ─ | ─ | • | • | • |

| Door – 2 Motorized | ─ | ─ | ─ | ○ | ○ |

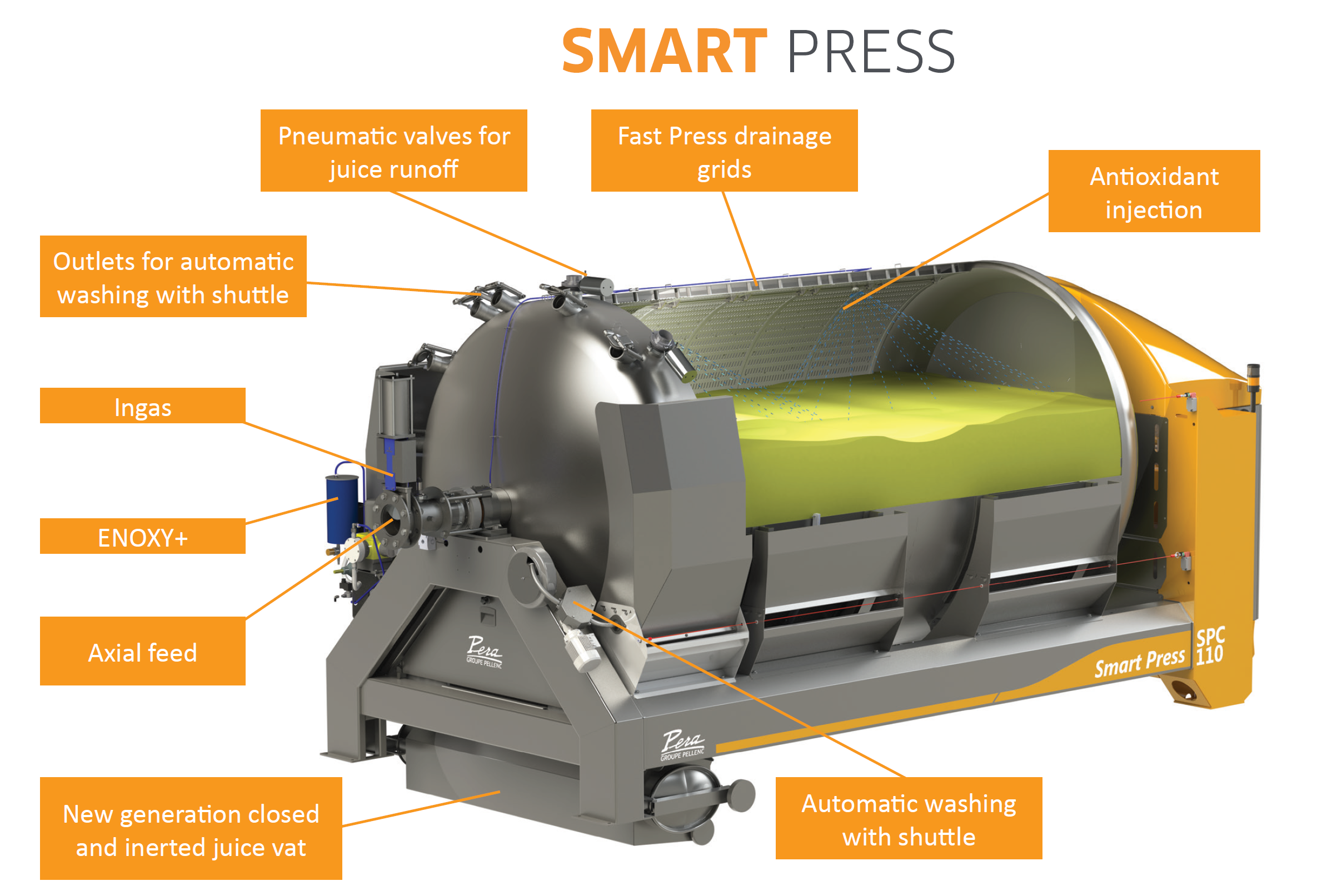

| Axial feed | Ø125 | Ø125 | Ø125 | Ø125 | Ø125 |

| 3x Juice outlets | ─ | ─ | • | • | • |

| Automatic wash | • | • | • | • | • |

| Automatic high-pressure wash | ─ | ─ | ○ | ○ | ○ |

| Fast Press Draining Grids | • | • | • | • | • |

| Electropolish Finish | ○ | ○ | ○ | ○ | ○ |

| Ingas | ─ | ─ | ○ | ○ | ○ |

| ENOXY + | ─ | ─ | ○ | ○ | ○ |

| Advanced Pressing Cycle | • | • | • | • | • |

| Easy Press 2 Cycle | ─ | ─ | ○ | ○ | ○ |

| Touchscreen | • | • | • | • | • |

| Capacity (hl) | SPC 110 | SPC 150 | SPC 240 | SPC 320 | SPC 480 | SPC 600 |

|---|---|---|---|---|---|---|

| Min quantity | 0 Kg | 0 Kg | 0 Kg | 0 Kg | 0 Kg | 0 Kg |

| Door – 1 Manual | ─ | ─ | ─ | ─ | ─ | ─ |

| Door – 1 Motorized | • | • | • | • | • | • |

| Door – 2 Motorized | ○ | ○ | ○ | ○ | ○ | ○ |

| Axial feed | Ø150 | Ø150 | Ø150 | Ø150 | Ø150 | Ø150 |

| 3x Juice outlets | • | • | • | • | • | • |

| Automatic wash | • | • | • | • | • | • |

| Automatic high-pressure wash | ○ | ○ | • | • | • | • |

| Fast Press Draining Grids | • | • | • | • | • | • |

| Electropolish Finish | ○ | ○ | ○ | ○ | ○ | ○ |

| Ingas | ○ | ○ | ○ | ○ | ○ | ○ |

| ENOXY + | ○ | ○ | ○ | ○ | ○ | ○ |

| Advanced Pressing Cycle | • | • | • | • | • | • |

| Easy Press 2 Cycle | • | • | • | • | • | • |

| Touchscreen | • | • | • | • | • | • |

SPO – Open Cage Presses

| Capacity (hl) | SPO 40 | SPO 50 | SPO 65 | SPO 80 | SPO 110 | SPO 150 |

|---|---|---|---|---|---|---|

| Min quantity | 0 Kg | 0 Kg | 0 Kg | 0 Kg | 0 Kg | 0 Kg |

| Door – 1 Manual | • | • | ─ | ─ | ─ | ─ |

| Door – 1 Motorized | ─ | ─ | • | • | • | • |

| Door – 2 Motorized | ─ | ─ | ○ | ○ | ○ | ○ |

| Axial feed | Ø125 | Ø125 | Ø125 | Ø125 | Ø150 | Ø150 |

| Total drainage plug, Sliding vat | • | • | • | • | • | • |

| Automatic wash | • | • | • | • | • | • |

| Automatic high-pressure wash | ○ | ○ | ○ | ○ | ○ | ○ |

| Half vat perforated with oblong holes | • | • | • | • | • | • |

| Ingas | ─ | ─ | ─ | ─ | ─ | ─ |

| ENOXY + | ○ | ○ | ○ | ○ | ○ | ○ |

| Advanced Pressing Cycle | • | • | • | • | • | • |

| Easy Press 2 Cycle | • | • | • | • | • | • |

| Touchscreen | • | • | • | • | • | • |