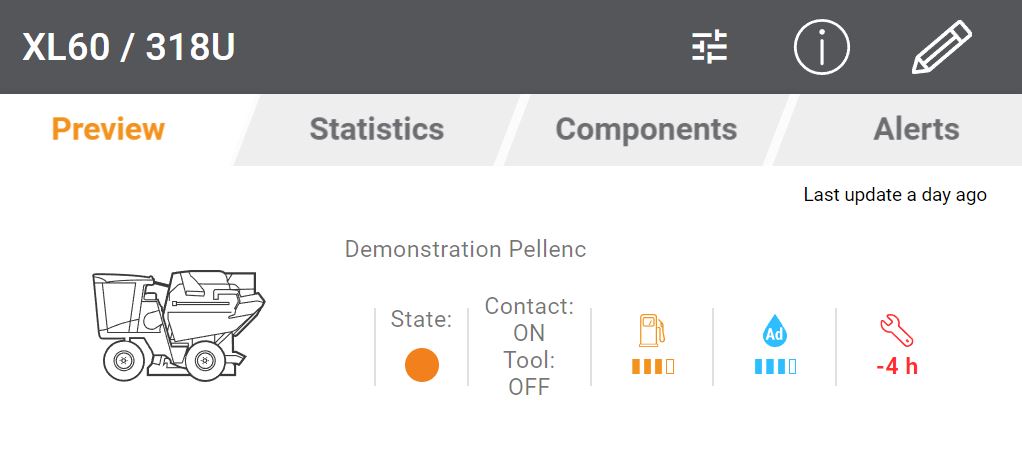

Pellenc Connect

CONNECTED WINEGROWING-WINEMAKING WITH PELLENC CONNECT

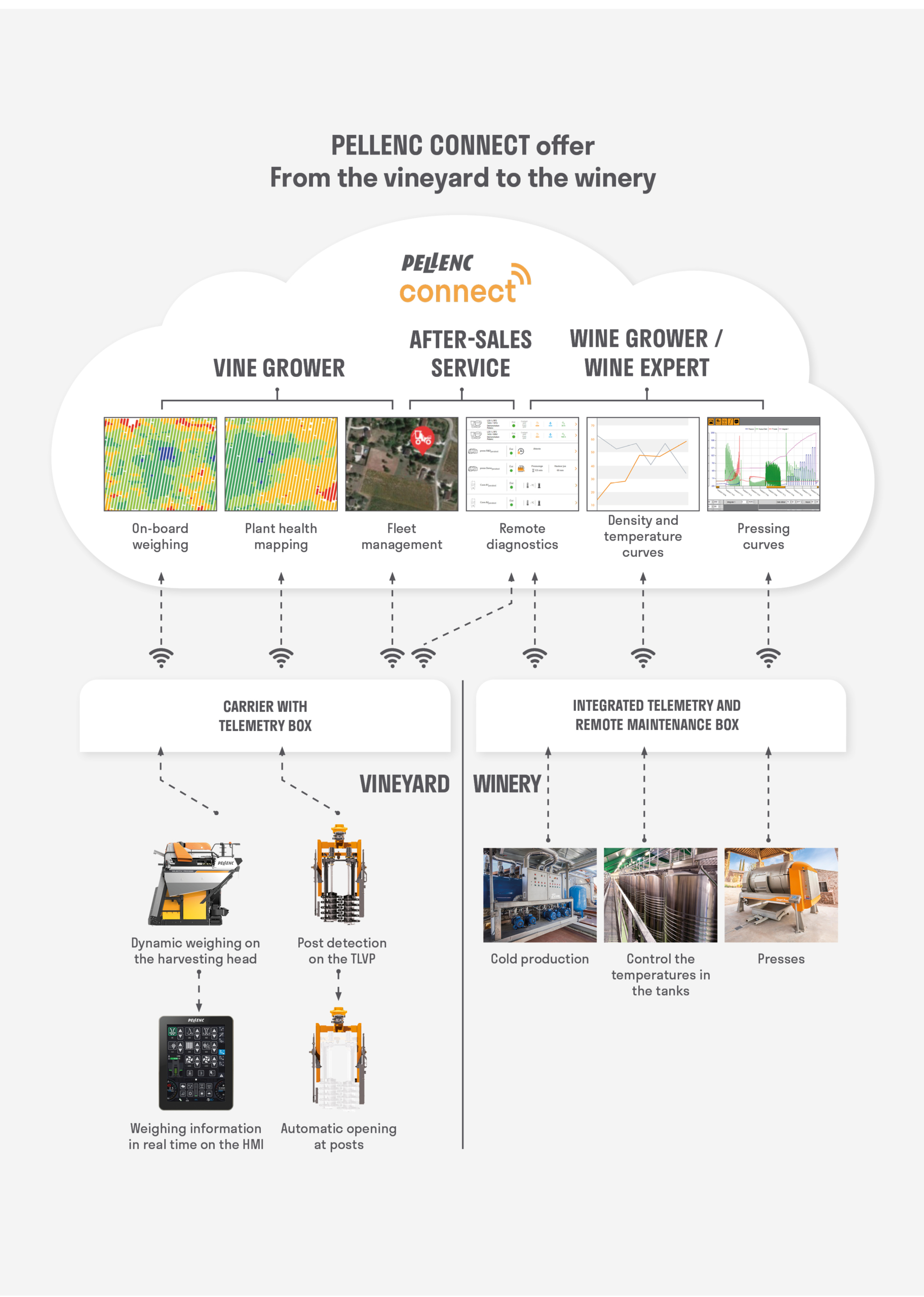

The new unique equipment monitoring platform is available for the PELLENC Group’s vineyard and winery machines, making life easier for the user and optimizing the operation of all the equipment.

PELLENC CONNECT also provides users with data about their machines, as well as agronomic and oenological data in real time for greater fluidity and responsiveness. This solution optimizes the organization of operations in the vineyard and the winery and allows the operator to perform the necessary tasks on the machines faster thanks to direct communication via the platform.

PELLENC CONNECT helps users better understand their production and raise their objectives in terms of the final product.

Precision vine-growing

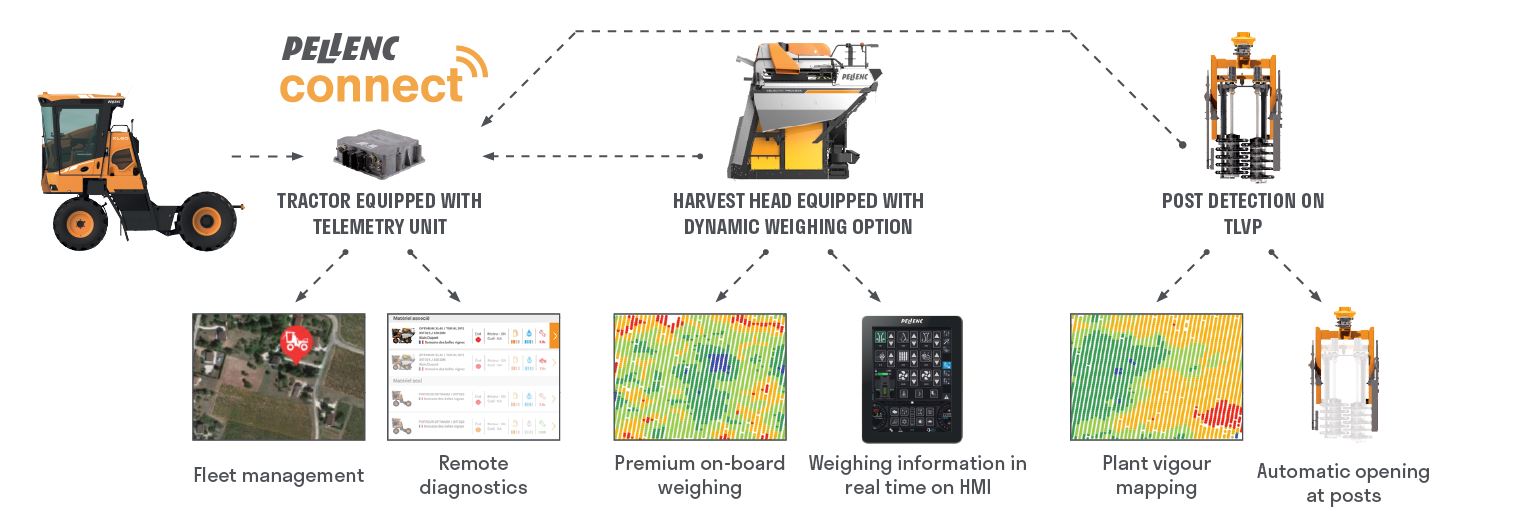

With your OPTIMUM multifunction carrier, optimize the monitoring and management of your vineyard using the agronomic data collected in the plots during work.

OPTIMUM lets you generate:

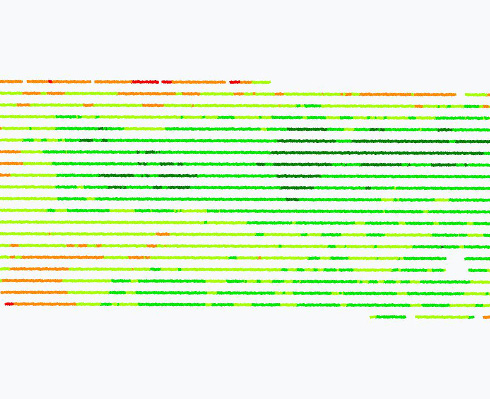

- Yield maps during the harvest

- Plant health maps during pre-pruning

The maps generated make it possible to optimize the potential of the vineyard plots by precisely controlling the following operations: fertilizations, pruning management, irrigation, phytosanitary spraying, replacement of plants, soil analyses, etc.

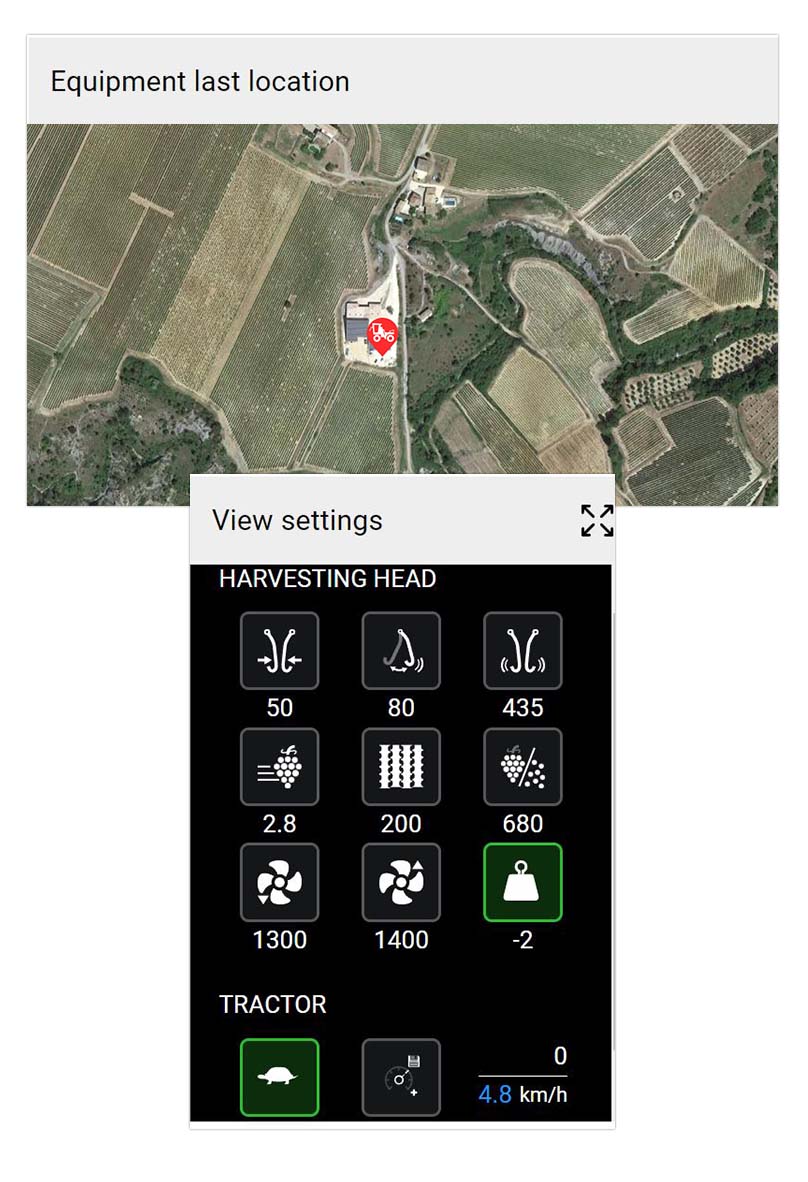

The PELLENC CONNECT platform strengthens the link between the vineyard and the winery by means of the following services:

- Information sharing to simplify the management of supply flows (e.g. optimizing the filling of tanks and presses)

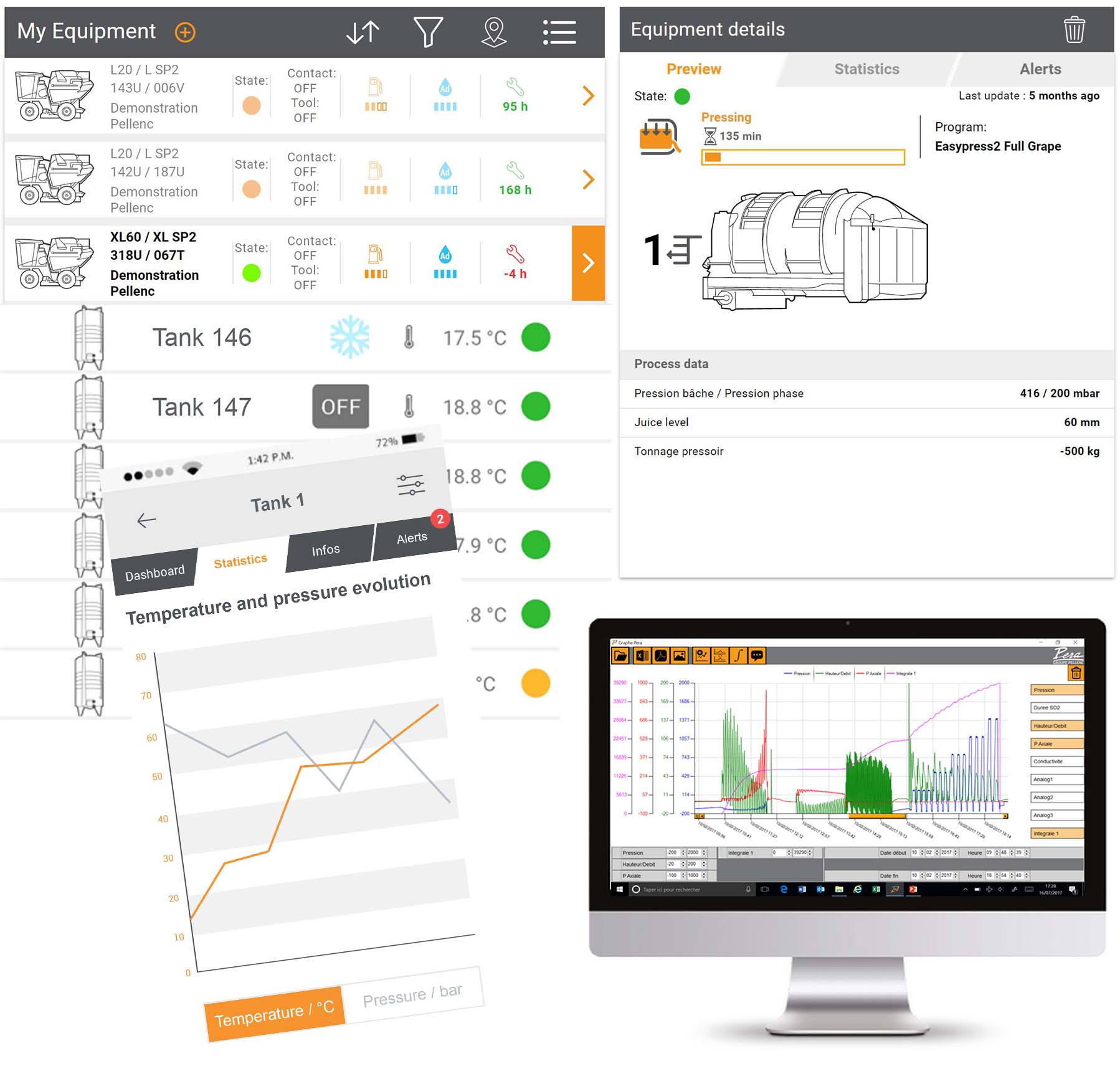

- Remote monitoring of equipment use

- Remote visualization of the equipment settings in the distribution fleet, as well as diagnostic data

- Visualization of all process information

- Maintenance interval reminders

- Fault alerts

- History of the use of the equipment and the associated settings in order to carry out a technical and economic analysis all the way “from the vineyard to the tank”

PELLENC CONNECT brings peace of mind to users while optimizing their activity: equipment management and monitoring of operations from the vineyard to the winery.

CONNECTED WINEMAKING

Services specific to cold production and temperature control:

- Remote control of the temperature in the tanks

- Display of information on cold production and distribution

Specific services for pressing:

- Information on the status of the press and the time remaining

- History and export of pressing curves for process analysis and optimization

The services provided by our experts to offer valuable advice:

- Analysis of the pressing curves to optimize the programs according to the desired oenological results.