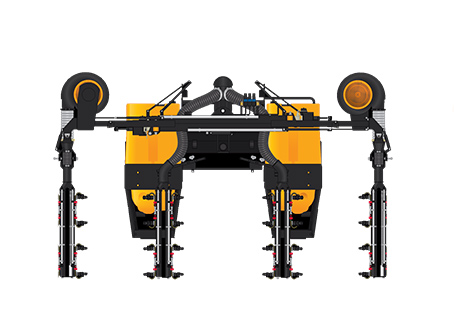

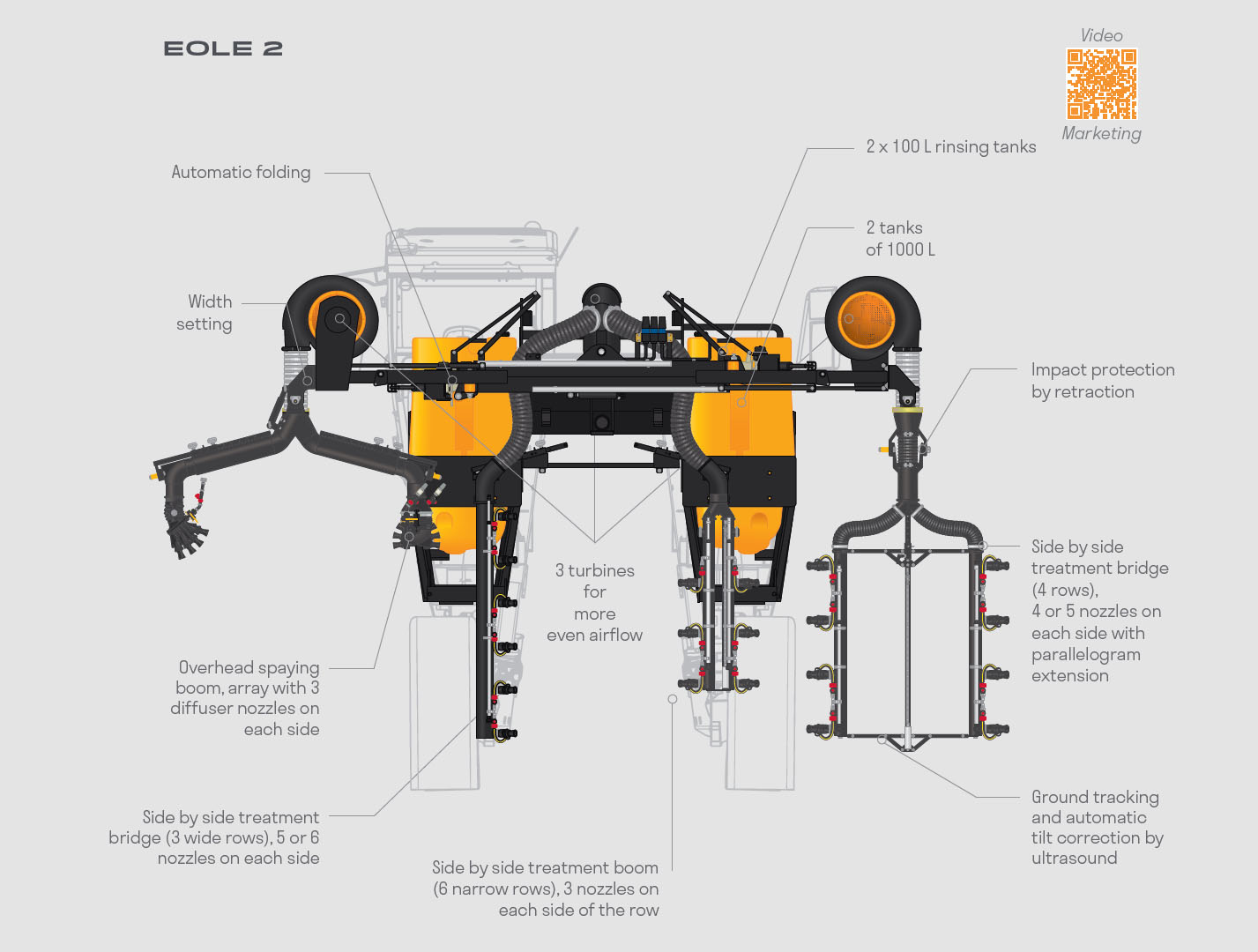

On narrow or wide vines, spray 3 to 6 rows at the same time. Carry out spraying with the help of pneumatic and air jet sprayers and take advantage of the Eole 2’s automated systems.

Cost-effective

- 3 turbines: economic performance.

- Drift on the ground and in the atmosphere limited through optimal and precise spray positioning.

- Adjustable diffusers depending on plant growth stage of the vines, without changing the hectare flow rate.

- Up to 30 % fuel savings.

Quality

- Precise positioning of spray on the plant canopy.

- Automatic ultrasonic ground tracking (slope correction of up to 30%).

- The turbines are positioned above the rows to ensure better distribution of the product.

- Optimum micronisation with pneumatic spraying.

- Reduced drift with air-blast spray.

- Powerful blending by hydrojets, provides a homogeneous mix in the tank for all types of products.

- Pump output of 25.3 gal/min at 20 bars.

Comfort

- Extremely easy to use with just one click (automatic opening and closing of the spraying booms).

- Plantation width setting from the cab’s control panel.

- Tank level visible from the cab: digital display.

Environment

- Thanks to the rinse circuit, effluents are significantly reduced.

- Pellenc carriers have wheels that are centred in the rows, thus ensuring the longevity of the vineyards.

- Drift is limited.

- Tanks washing is completed with rotary nozzles (optional).

- Up to 30% fuel consumption.

- Flow-rate directly proportional to ground-speed so the programmed dosage is respected.

- Preserves the root system (wheels are centred on the row).