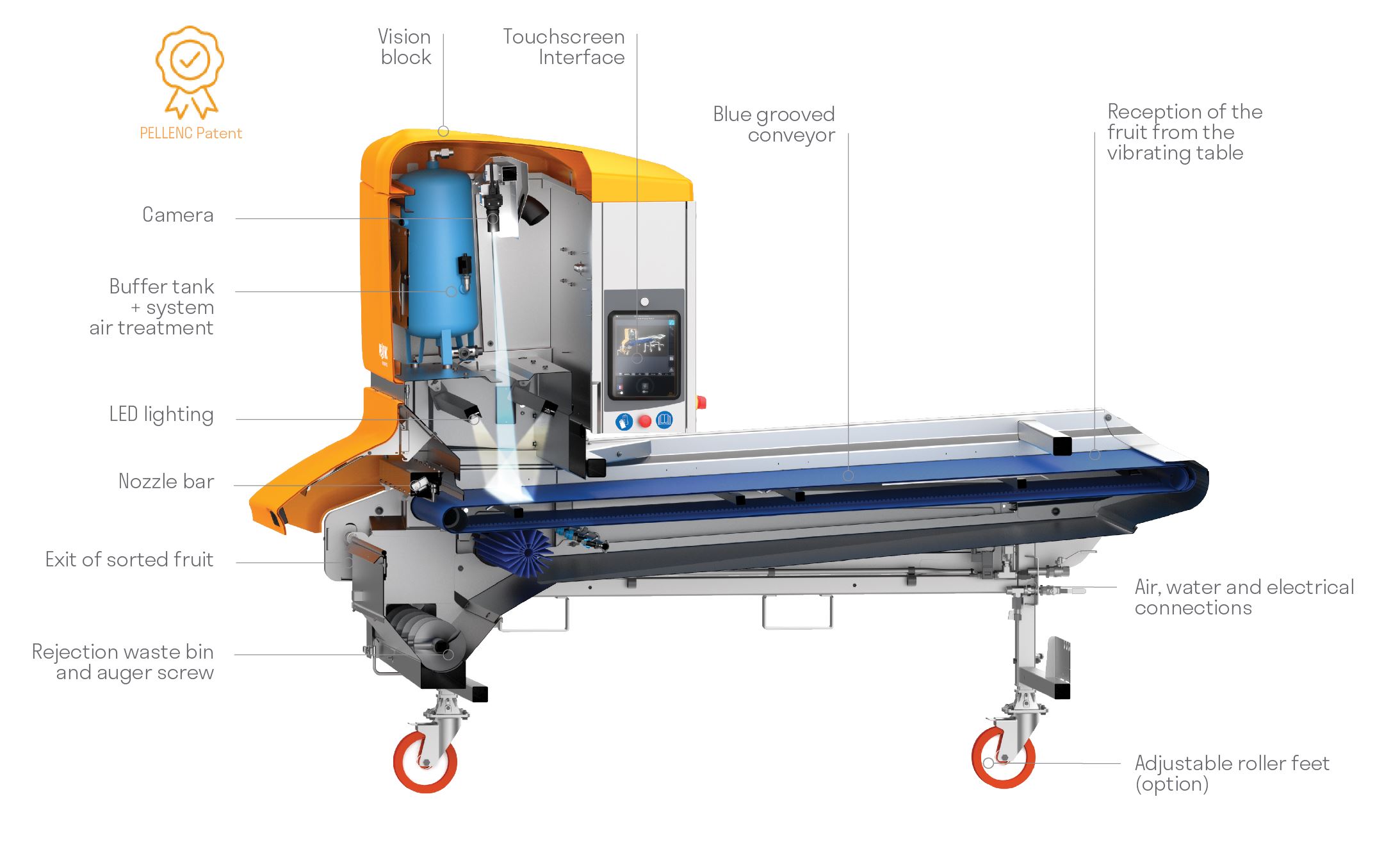

Selectiv’ Process Vision 3

A perfect sorting for exceptional wines

Intuitive

- Simple icon-based touchscreen provides immediate changes to the sorting algorithm.

- No calibration needed: start using right away!

Cleaning efficiency

- Pre-cleaning while running with automatic brush to help reduce build up on belt conveyor decreases the required cleaning time.

- Easy to open panels for cleaning.

Cost-Saving

- Significant reduction in labor costs

- Optimizes the quality of your wines

Quality

- Constant and complete sorting

- Designed for wine grape varieties

- Choose the sorting level in real-time according to the desired quality

- This perfect sorting has a direct positive impact on the quality of the wines.

Simple and intuitive adjustment

- A new tactile and intuitive interface allows you to make all the settings of the machine. The ability to change the brightness allows visibility in all situations.

Easy cleaning

- The cleaning-in-place system of the belt as well as the easy access to the various parts of the machine reduce washing times and water consumption.

Technical characteristics

|  | |

| SELECTIV’ VISION 3 | VIBRACTIV’ 3 | |

| Flow (depending on grape variety, maturity, health status, water stress and desired sorting quality) * | Up to 12t / h | Up to 12t / h |

| Length (overall in mm) | 3,040 ( 199.7 in ) | 1,675 ( 66 in ) |

| Width (overall in mm) | 1,870 ( 73.6 in ) | 1,420 ( 55.9 in ) |

| Total height (min-max) (in mm) | 2,160-2,580 (85 in – 101.6 in ) | 1,300-1,850 ( 51.2 in – 72.8 in ) |

| Grape outlet height (min-max) (in mm) | 600-1,025 ( 23.6 in – 40.35 in ) | N/A |

| Machine weight (all options) in kg | 850 ( 1874 lbs ) | 275 ( 606 lbs ) |

| Rated power (kW) | 2.6 | 0.6 |

| Power supply | 16A 3P + ( USA 480v ) | 16A 3P +( USA 480v ) |

| Air supply | 50m3/h at 7 bars (30cfm @ 100psi) | N/A |

| Manufacturing material | Inox 304 L | Inox 304 L |

| Conveyor speed (in m / s) | 2.4 ( 7.9 ft/s ) | N/A |

| Pneumatic tank (2 x 24 L) + air treatment | • | N/A |

| Pre-cleaning in place | • | N/A |

| Vision unit waste collection tray with evacuation screw | • | N/A |

| Height-adjustable castor feet | option | • |

| Management of peripheral systems (Extractiv ‘, Selectiv’ Winery, etc.) | option | N/A |