2021 Unified Show

GET A QUOTE

Welcome to Pellenc America’s 2021 Unified Portal

This year we’re participating in the virtual tradeshow and we’re glad you stopped by! We have sales representatives and product experts on hand to help answer questions. We’ll also be releasing videos during the week of the show, right here, so check back for more new content all week! Also, be sure to take a minute and sign up for our newsletter for a chance to win PELLENC hats!

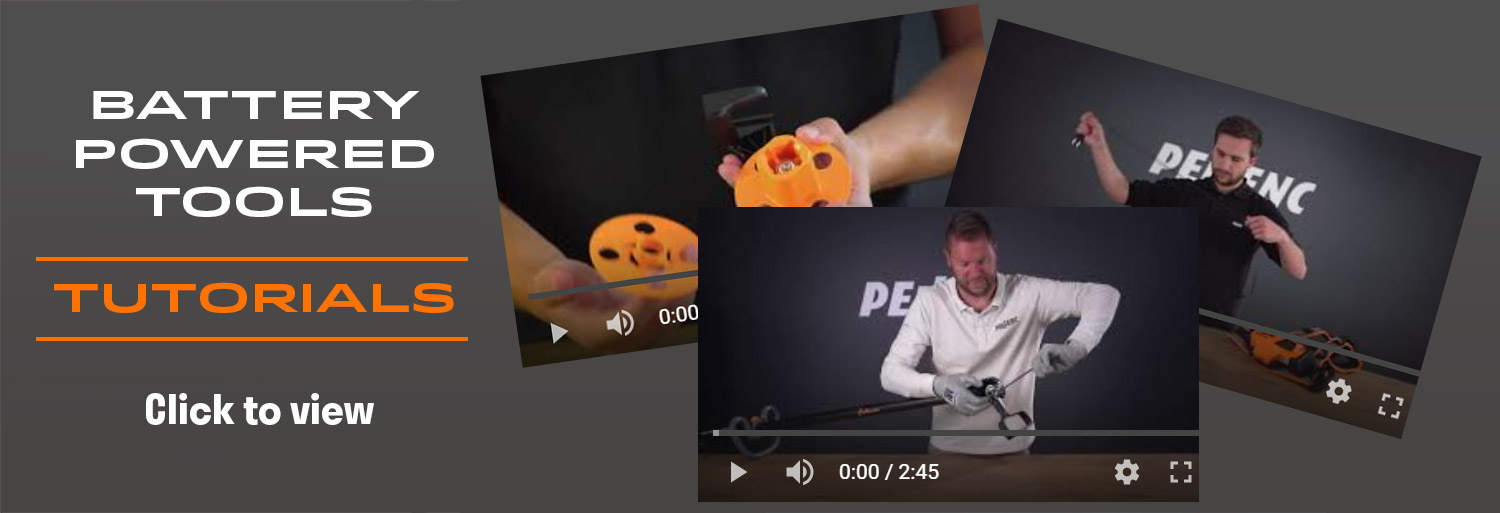

IN-DEPTH VIDEOS

We’ve produced a few in-depth videos on some of our newest products, updates and testimonials. Be sure to take a few minutes and check them out! Learn the ins-and-outs with Pellenc America experts as we give you an insiders look.

Battery Powered Tools

Precision Pruner

Oenopompe & Smart Glass

Under Vine Cultivator

Testimonial

Testimonial

Testimonial

KLIMA Cane Pruning

Selectiv’ Process

VINEYARD MANAGEMENT

We’ve got a Pellenc 890, this is our third season running that harvester. We’ve been using machine harvesting and machine harvested fruit for probably 25-30 years now and when they came out with the onboard sorting system, the Selectiv’ Process…that’s what really pushed us towards Pellenc. The fruit that’s coming out of that machine is very very clean there’s hardly any leaves, very few stems, and it can go right in a tank without any further processing once it gets to the winery. For us at Silver Oak that’s really important. One of the factors that caused us to buy a machine to go to machine harvesting is the ability to be able to pick when we want to pick. For us, a day or two later than we want to really makes a huge difference in fruit quality. So being able to pick the amount we want, the time we want and keep on that schedule is really important. We’ve been very satisfied with the quality of the equipment. It’s in three seasons that we’ve been running it, we’ve had just a few minor issues that got straightened out quickly. Can’t say enough about the service department, they do a great job. They’re available 24/7 and we’ve used them a couple of times at all hours of the night. We chose this machine because we think it’s the best in the industry right now.

When you work at a certain level of quality, every piece of equipment and every detail takes a greater importance. In order to make sure that your decisions are applied and respected and have the effect that you’re looking for, you have to have reliable equipment and precision equipment. The motivation in purchasing Pellenc equipment was to standardize a certain level of that single operation. When you make wine that are expensive, but hopefully also made to age through time, you want consistency and quality. And Pellenc came in with their optical sorter, not only making what was done by hand much more efficient, but much more cost effective, but much more consistent. You can imagine that when you have a person looking at a moving target for six, seven, eight hours in a row, at a certain speed, they lose attention fairly fast. The machine doesn’t. The machine is extremely precise, and so certain very determined parameters that actually sort the grapes the way you want to to ensure that when the grapes end up in the vessel for its fermentation, they all have the same characteristics. And so whatever decision you’re gonna apply to them will be uniform.

We’ve got a Pellenc 890, this is our third season running that harvester. We’ve been using machine harvesting and machine harvested fruit for probably 25-30 years now and when they came out with the onboard sorting system, the Selectiv’ Process…that’s what really pushed us towards Pellenc. The fruit that’s coming out of that machine is very very clean there’s hardly any leaves, very few stems, and it can go right in a tank without any further processing once it gets to the winery. For us at Silver Oak that’s really important. One of the factors that caused us to buy a machine to go to machine harvesting is the ability to be able to pick when we want to pick. For us, a day or two later than we want to really makes a huge difference in fruit quality. So being able to pick the amount we want, the time we want and keep on that schedule is really important. We’ve been very satisfied with the quality of the equipment. It’s in three seasons that we’ve been running it, we’ve had just a few minor issues that got straightened out quickly. Can’t say enough about the service department, they do a great job. They’re available 24/7 and we’ve used them a couple of times at all hours of the night. We chose this machine because we think it’s the best in the industry right now.

When you work at a certain level of quality, every piece of equipment and every detail takes a greater importance. In order to make sure that your decisions are applied and respected and have the effect that you’re looking for, you have to have reliable equipment and precision equipment. The motivation in purchasing Pellenc equipment was to standardize a certain level of that single operation. When you make wine that are expensive, but hopefully also made to age through time, you want consistency and quality. And Pellenc came in with their optical sorter, not only making what was done by hand much more efficient, but much more cost effective, but much more consistent. You can imagine that when you have a person looking at a moving target for six, seven, eight hours in a row, at a certain speed, they lose attention fairly fast. The machine doesn’t. The machine is extremely precise, and so certain very determined parameters that actually sort the grapes the way you want to to ensure that when the grapes end up in the vessel for its fermentation, they all have the same characteristics. And so whatever decision you’re gonna apply to them will be uniform.

Email

Emailinformation@pellencus.com

(707) 568-7286

Email

Emailinformation@pellencus.com

(707) 568-7286

Email

Emailinformation@pellencus.com

(707) 568-7286

3171 Guerneville Road Santa Rosa, CA 95401 United States

Tel. +1 (707) 568 7286

Email : information@pellencus.com