Weeder – Under Vine Cultivator

/in In-row Tractor, Optimum Carrier /by adminx1

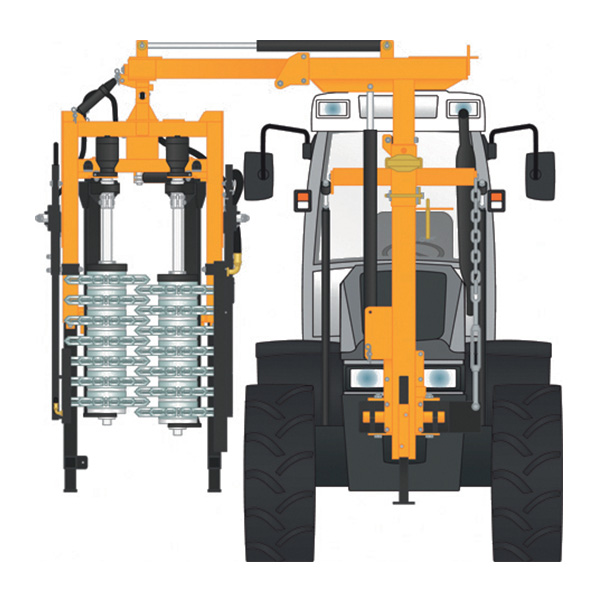

The Under-the-Vine weeder and optional rotary tillers

Equipped with (2) electro hydraulic weeders and a self contained hydraulic power pack, it is effective in many types of soil conditions. The unit comes with a control panel for installation in the tractor cab. This weeder is designed to work around young vines, even with a very small size (from 1/2in diameter).

Weeder blades are controlled by an adjustable sensing rod. The system combines a parallelogram design with radial movement that enables high accuracy.

Working (2) 1/2 rows per pass at speeds up to 5 mph provides good efficiency.

| Model | Description | Cutting length | Row Distance | Weight | Hp | L | W | H |

|---|---|---|---|---|---|---|---|---|

| CR-S-IA-P | Reversible chassis 2 In row weeder | 55cm 1’ 9” | 1.85 – 2.60 6ft – 8.5ft | 370 kg 815 lbs | 40 hp | 1.25m (4.1ft) | 1.30m (4.26ft) | 1.25m (4.1ft) |

| CR-M-IA-P | Reversible chassis 2 In row weeder | 55cm 1’ 9” | 2.45 – 3.20 8ft – 10.5ft | 450 kg 992 lbs | 45 hp | 1.25m (4.1ft) | 1.90m (6.23ft) | 1.25m (4.1ft) |

| CR-L-IA-P | Reversible chassis 2 In row weeder | 55cm 1’ 9” | 3.00 – 4.10 9.8ft – 13.4ft | 460 kg 1014 lbs | 50 hp | 1.25m (4.1ft) | 2.40m (7.87ft) | 1.25m (4.1ft) |

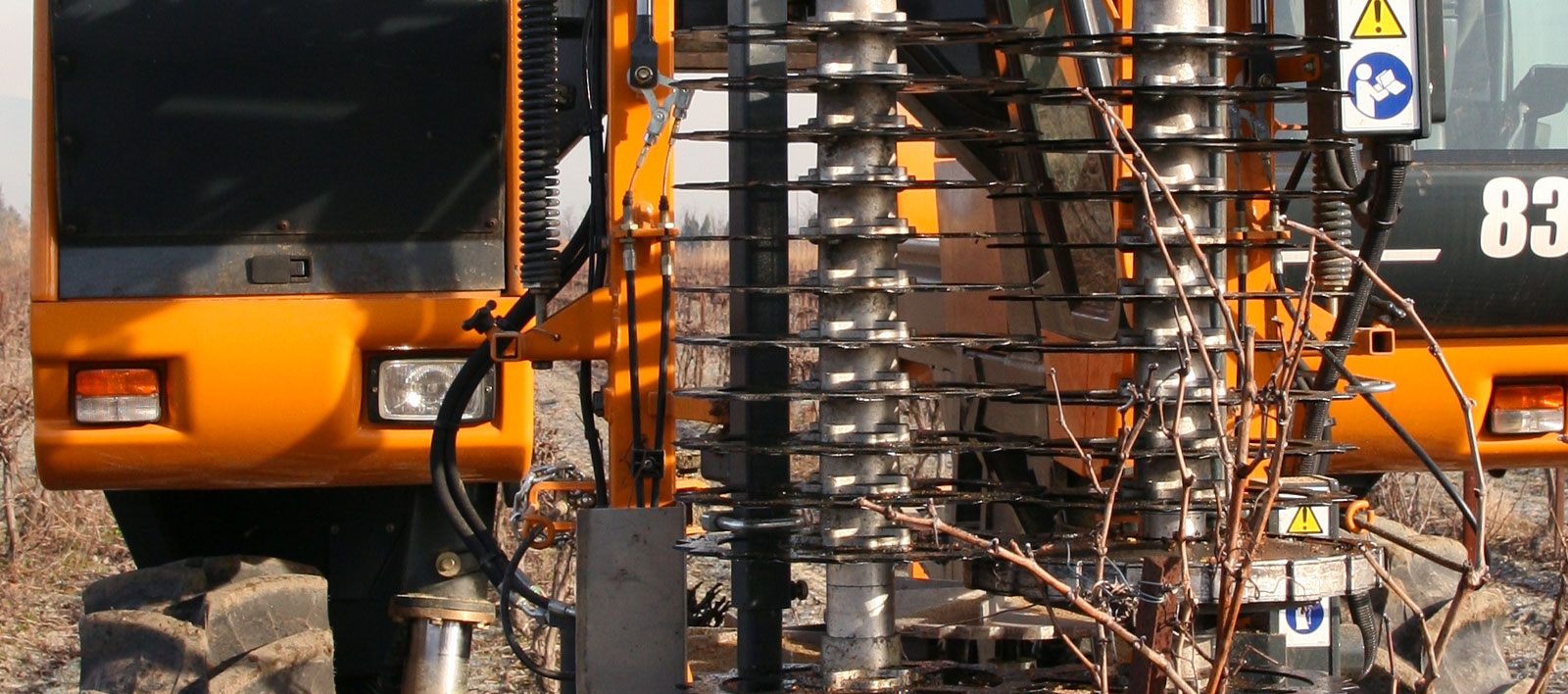

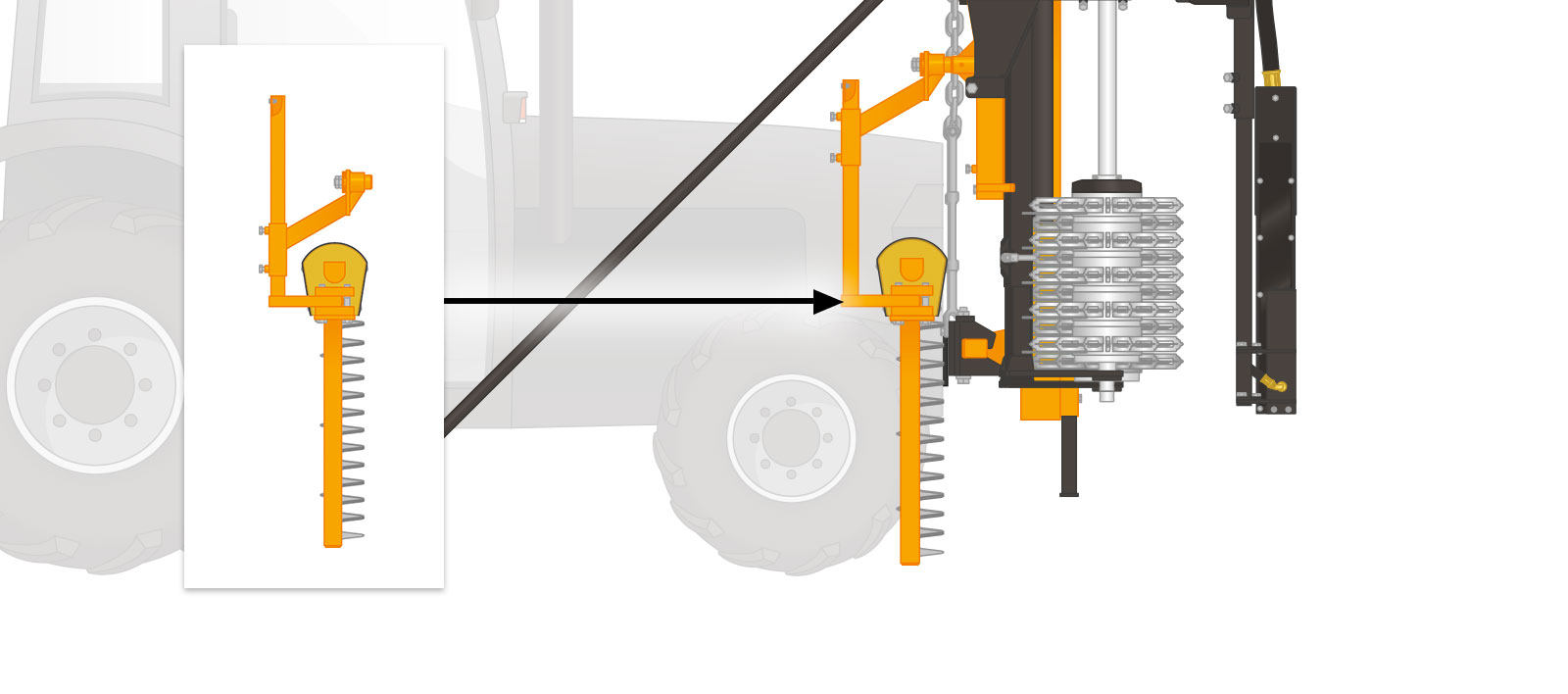

Pruner – Klima Cane Pruner

/in In-row Tractor /by adminx1

Precision cane pruning.

The KLIMA cane pruning system, supported by Pellenc America, is operated after an initial pass by skilled pruners. The Klima cane pruner rapidly removes the canes, strips them from the wires and mulches them in a single pass from your in-row tractor or Optimum front arm.

Cost-effective Cane Pruning

- Operate in vineyards with undulating terrain

- Operate in vineyards with poor quality wire, mild steel etc

- Operate with less wire breakages in all condition

- Suitable for small tractors built for narrow rows

- Self contained mast – no need for you to purchase a front end loader

- Small and consistent organic mulch size for speedy breakdown

- Easy to pick up and drop out wires – you will be an expert in less than a day

- Enjoy the simple and comfortable joystick controls with adjustments to suit any driver

Features

Strong, robust and fully self contained, KLIMA Generation 2 fits on to the front of a cab tractor or crawler. A minimum of 80Hp and 12 GPM at 2900PSI of hydraulic oil supply is required.

Tractor Requirements

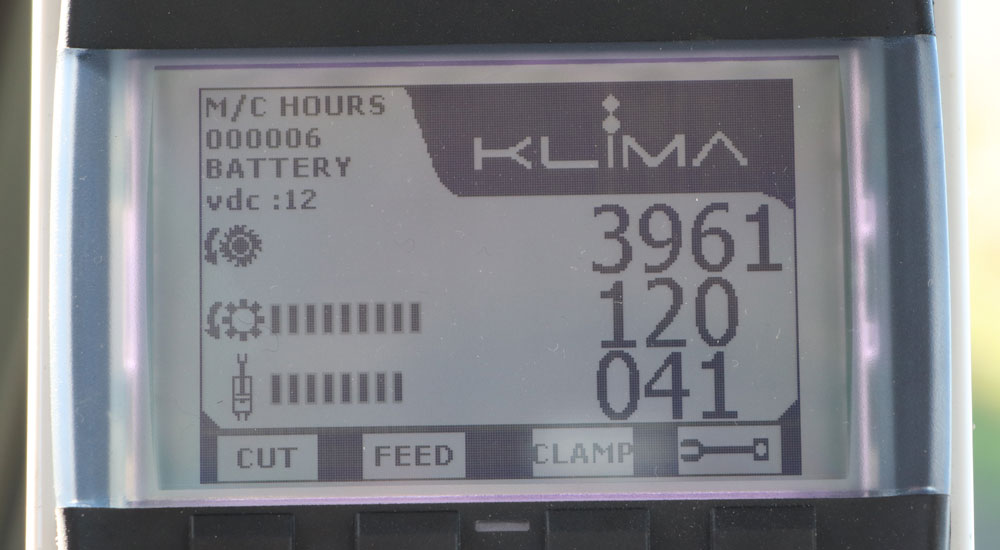

Simple and intuitive joystick control and display system provides optimum driver comfort and control.

Control system

The unique, patented cutting and feeding system is the reason the KLIMA G2 design is a universal and fully adaptable tool for your vineyard.

Cutting Head

Head rotates to be used on the left or right side of the tractor.

Reversible Cutting Head

GRAPES’LINE tow behind harvester

/in In-row Tractor /by adminx1

The Grapes’Line tow behind harvester includes all the latest PELLENC innovations. It has a harvesting capacity of 3,600 litres (950gal) – the same as that of a self-propelled harvester – while remaining less costly. Highly efficient, it also provides wine-growing professionals with an unrivalled work quality thanks to its easy handling and user-friendly nature.

Efficient

- Harvesting capacity identical to a self-propelled harvester

- 50% cheaper than a self-propelled machine

- ECO POWER fuel management: optimised power take-off according to the machine’s hydraulic requirements

- Total collector-bin capacity of up to 3,600 litres (950gal)

Excellent work quality

- Flexible Sorter Conveyor: up to 5% more harvest in your collector bins!

- New tortoiseshell shape: optimal sealing

- New generation harvesting arm

- SELECTIV PROCESS: 99.82% clean harvest

Ergonomic

- 7-inch touchscreen

- Safe washing platform

- Remote washing commands

- Centralized greasing

Easy to handle

- Auto-guidance in the row

- Semi-automatic tilt correction

- Optimized turnaround in headlands with the wide-angle drawbar

- AUTO TORQUE drive: machine-independent on slopes and in headlands

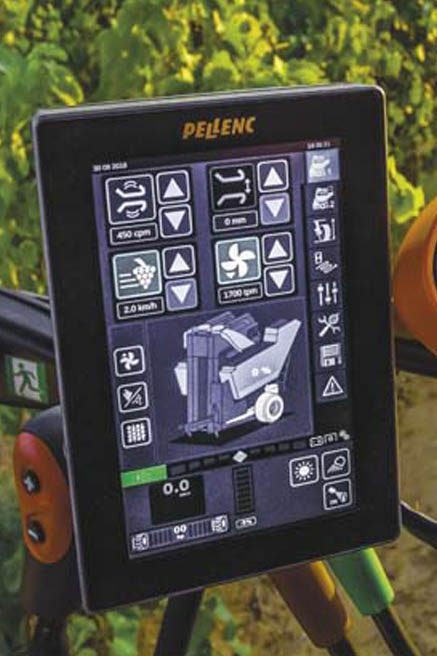

Control interface

‘EASY TOUCH’ interface: models 60 and 80

- 7-inch touchscreen.

- Working comfort.

- Icons and intuitive menus.

- Harvest parameters managed from the cab with the EASY TOUCH screen.

Driving assistance:

- Automatic height stops at work and in headland turnarounds.

- Ground detection with sensors.

- Instant display of slope, gradient percentage, and machine height.

- Bin-level indicator.

- Acreage counter.

Interface with remote controls on machine

- Simple control and use of harvesting parameters from the machine.

‘EASY DRIVE’ control: all models

- All your GRAPES’LINE functions on the PELLENC joystick.

Easy to handle

In the row

- With the ‘ACTIV’’ auto-guidance system, the harvesting head is automatically centred in the row. Joystick buttons always take priority. An alarm notifies the driver if there is a blockage from a foreign body; the vineyard is always protected.

- Tilt correction up to 70 cm (27.5in) allows working on any ground surface.

In headlands

- The articulated coupling helps attachment and improves safety.

- The wide-angle drawbar helps maneuvering in the headland.

- The ‘AUTO TORQUE’ drive controls the power to the wheels, even in headlands, without the need for the joystick.

On the road

- The wide-angle drawbar keeps the harvesting head in line with the tractor on the road.

- The bins are only 2.50 metres wide(8.2ft), which makes manoeuvring and driving on the road easier.

Revolutionary harvesting system

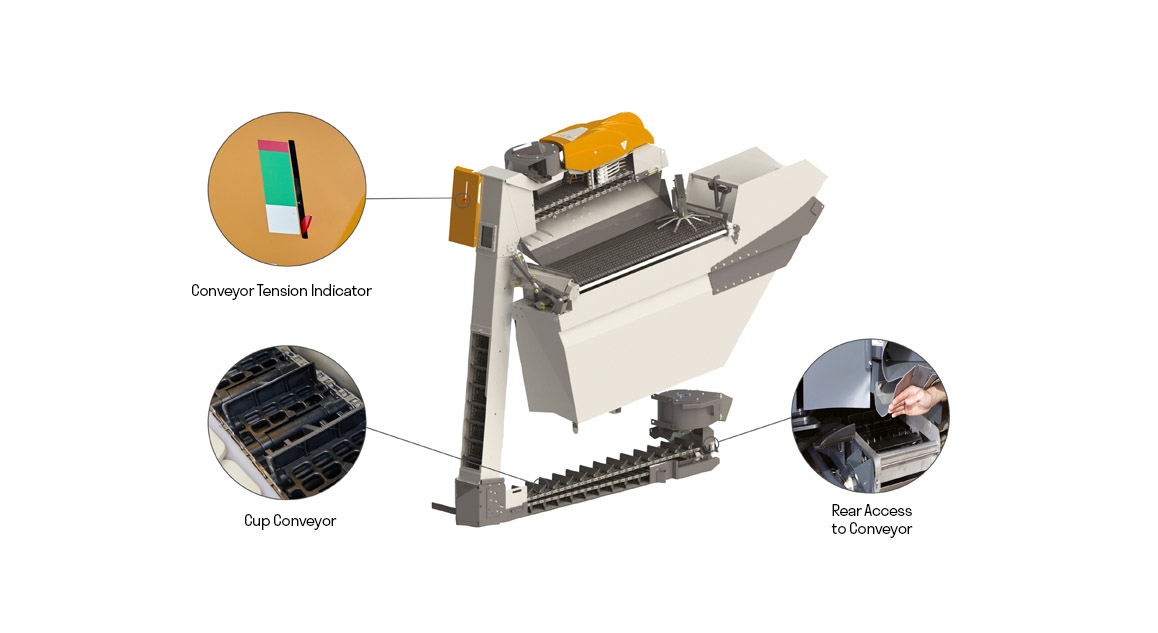

Flexible Sorter Conveyor

- The innovative design of the flexible sorter conveyor starts the grape sorting from the chute.

- Only 30% of the harvest passes under the fans: up to 5% more harvest.

- Semi-automatic conveyor tensioning makes maintenance easier and ensures the correct tension.

- The system can be fully dismantled to reduce maintenance costs.

- Quick cleaning.

- No need to dismantle the conveyors at the end of the season.

L-shaped design of the conveyor

- Conveyor open at the back to remove foreign material and avoid clogging.

- Work at ground level with its protective steel housing.

- The conveyor is made of stainless steel to make maintenance and washing easier.

Harvest quality

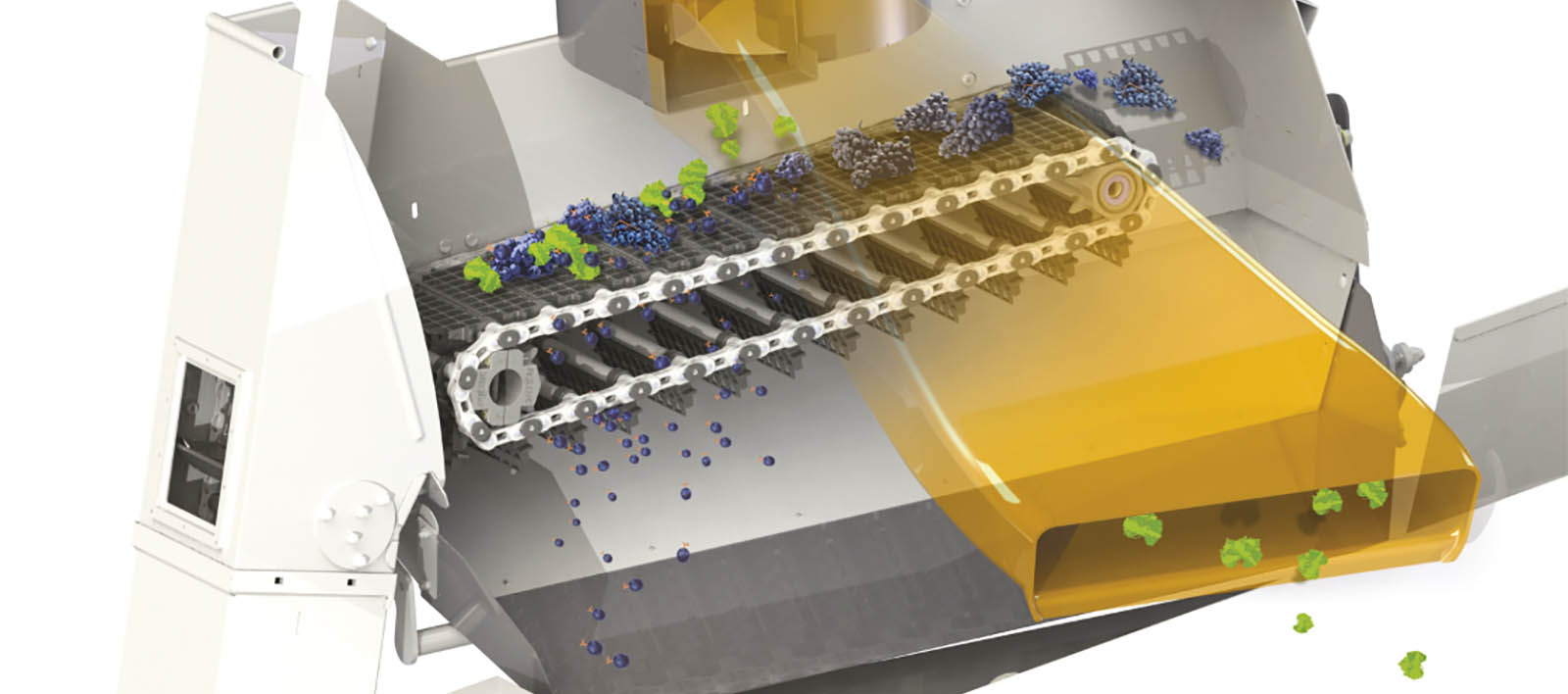

‘SELECTIV’PROCESS’: De-stemmer + Sorting Tables

Destemmer

- Destem and sort your harvest in the field to go directly into the tank.

- Tried and tested by over 2,000 users.

High-frequency linear destemmer

- Destemming without loss, even for difficult grape varieties, while preserving the berries. The feed belt helps removes foreign bodies.

Variable sorting table and sorting roller

- The solid notched roller feeders route leaf stems to the sorting rollers.

- The sorting rollers allow the sorted berries to pass through and remove the leaf stems and other waste from the sorting table.

- The variable screen sorting table adjusts quickly to all grape varieties and all working conditions.

- 100% of leaves are removed as well as 95% of leaf stems.

Sorter

Bin capacity

Smart hydraulic management

Hydraulic control unit

AUTO TORQUE drive system

- The machine adjusts its speed automatically to that of the tractor, based on the traction force on the towing ring.

- The machine is independent in all working situations: forward or reverse, as well as in headlands.

- The driver can concentrate on driving.

- The ‘AUTO TORQUE’ automatically supplies the power needed at the right time, without the driver having to do anything.

- The ‘AUTO TORQUE’ drive can handle gradients of up to 30%.

‘ECO POWER’ control

- Optimisation of power take-off according to the machine’s hydraulic requirements, in order to ensure the lowest possible engine speed and save on fuel.

Pellenc advantages

New generation of harvesting arms

New shape of catcher trays

Easy to maintain

Safe

Technical features

| GRAPES’ LINE | 60 | 80 |

|---|---|---|

| DIMENSIONS | ||

| Minimum plantation width | 1.40 m (4.6ft) | 1.70 m (5.57ft) |

| Tractor power required | 70hp | 80hp |

| Overall height (m) | 3.38 m (11.1ft) | 3.42 m (11.2ft) |

| Bin width (m) | 2.50 m (8.2ft) | 2.50 m (8.2ft) |

| Maximum slope | 27% | 27% |

| Maximum gradient without sorting equipment | 30% | ─ |

| Maximum gradient with sorting equipment | ─ | 25% |

| Tires | 400/70-20 | 400/70-20 |

| Option | 340/80R20 | |

| CONTROL INTERFACE | 60 | 80 |

| ‘EASY DRIVE’ joystick | • | • |

| Easy Touch 7” screen | • | • |

| Remote controls | ─ | ─ |

| HYDRAULIC MANAGEMENT | 60 | 80 |

| ‘AUTO TORQUE’ drive | • | ─ |

| Wheel motor with hydraulic brake | • | • |

| Dual-line hydraulic braking | • | • |

| Hydraulic attitude correction | • | • |

| ECO POWER mode | • | • |

| DRIVING ASSISTANCE | 60 | 80 |

| Slope display | • | • |

| % gradient display | • | • |

| Working-height display | • | • |

| Upper and lower stops | • | • |

| Ground detection | • | • |

| Acreage counter | • | • |

| SAFETY | 60 | 80 |

| Number of emergency-stop buttons | 4 | 4 |

| Reversing alarm | • | • |

| Bin-lowering alarm | • | • |

| Rear camera visible on Easy Touch | • | • |

| Working lights | • | • |

| Tilt correction | • | • |

| HARVESTING HEAD | 60 | 80 |

| Auto-guidance with blocking alarm | • | • |

| Post shock protector | ○ | ○ |

| Sealing length at ground level | 2.62 m (8.6ft) | 2.62 m (8.6ft) |

| Harvest transport by flexible sorter conveyor | • | • |

| Safety in the event of conveyor blockage | • | • |

| Semi-automatic tensioning of the flexible sorter conveyor | • | • |

| Two height-adjustable lower suction fans | without tools | without tools |

| Leaf sorter | • | ─ |

| Sorting device: Destemming + sorting table | ─ | Selectiv’Process |

| Bins | 2×1,800L (2x475gal) | 2×1,600L (2x422gal) |

| Optional bins | 2×1,250L (2x330gal) | ─ |

| Bin auger | • | • |

| Bin-level indicator | • | • |

| Bin-emptying axis height | 3 m (9.84ft) | 3 m (9.84ft) |

| MAINTENANCE | 60 | 80 |

| Grouped greasing points | • | • |

| Remote washing control | • | • |

| Safe access platform | • | • |

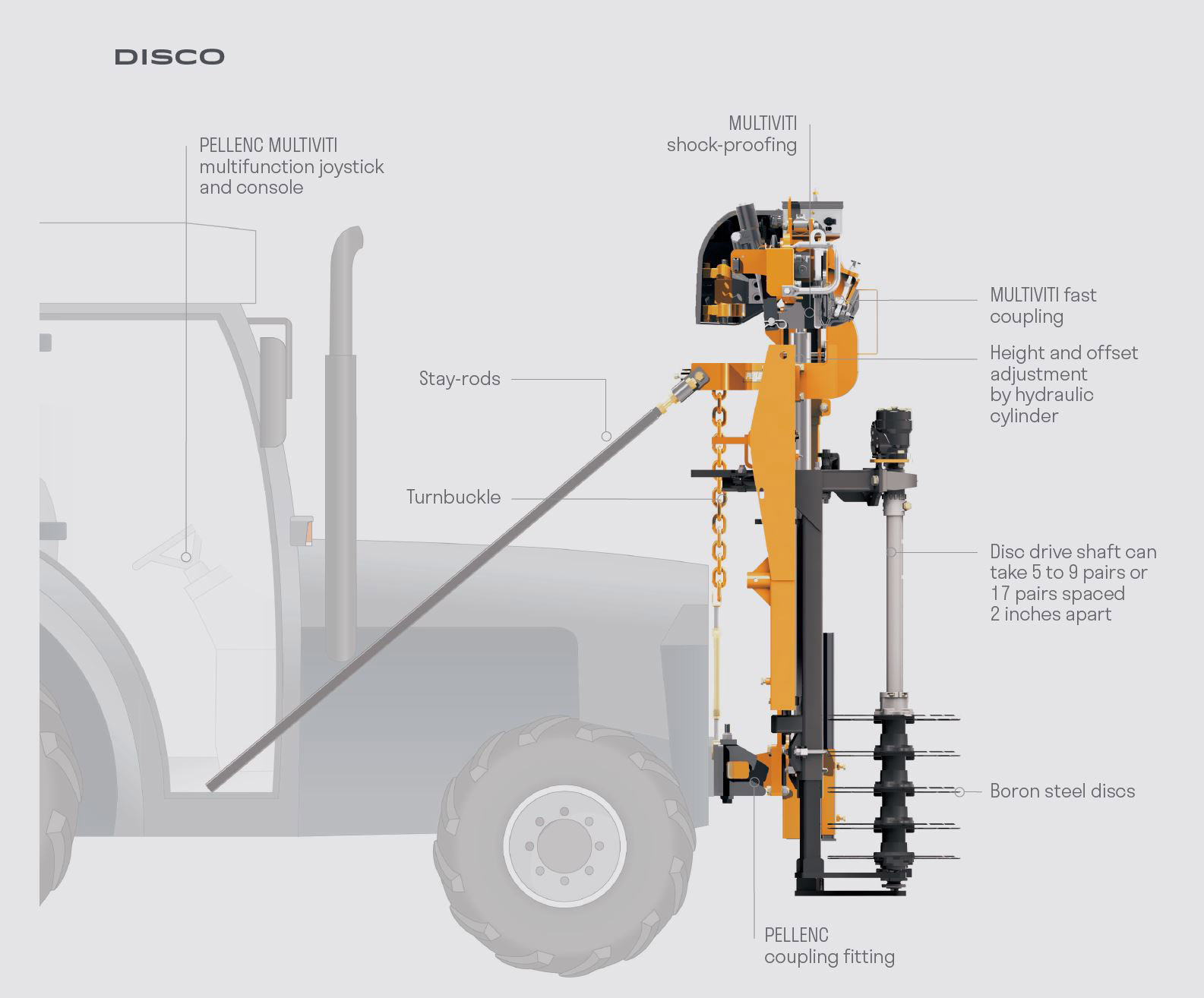

Pre-Pruner – Disco

/in In-row Tractor, Optimum Carrier /by adminx1

SIMPLE AND ECONOMICAL

Work more cost effectively with the DISCO pre-pruner. Its simplicity allows it to work quickly and efficiently and means that it’s easy to maintain.

COST-EFFECTIVE

- Working speed up to 3MPH for optimum work, even in dense vegetation.

- Low hydraulic requirement (6.6 gal/min).

- Coupling with Multiviti in 3 minutes.

- No sharpening of discs required.

- No more removing wood.

Precise adjustment of the discs for a clean cut

Its light weight allows us to work quickly in all our blocks. Its small footprint together with the reduced overhang makes it extremely stable on slopes. Maintenance is fast and simple, and it offers excellent visibility. What a comfort! It does its job well, performing quality work regardless of the amount of wood in the row, and without special wear considering the 667.2 acres worked.

CLEAN CUTTING

- Good grip of vine shoots and clean cutting with the specially shaped discs.

- Cutting close to the cordon by precise adjustment of the distance between the two lower discs.

- Each stack of discs is adjustable in relation to the other for better cutting quality and easier removal of tendrils.

USER-FRIENDLY

- Very quiet operation.

- Electrical control of all functions.

- Joystick and ergonomic console.

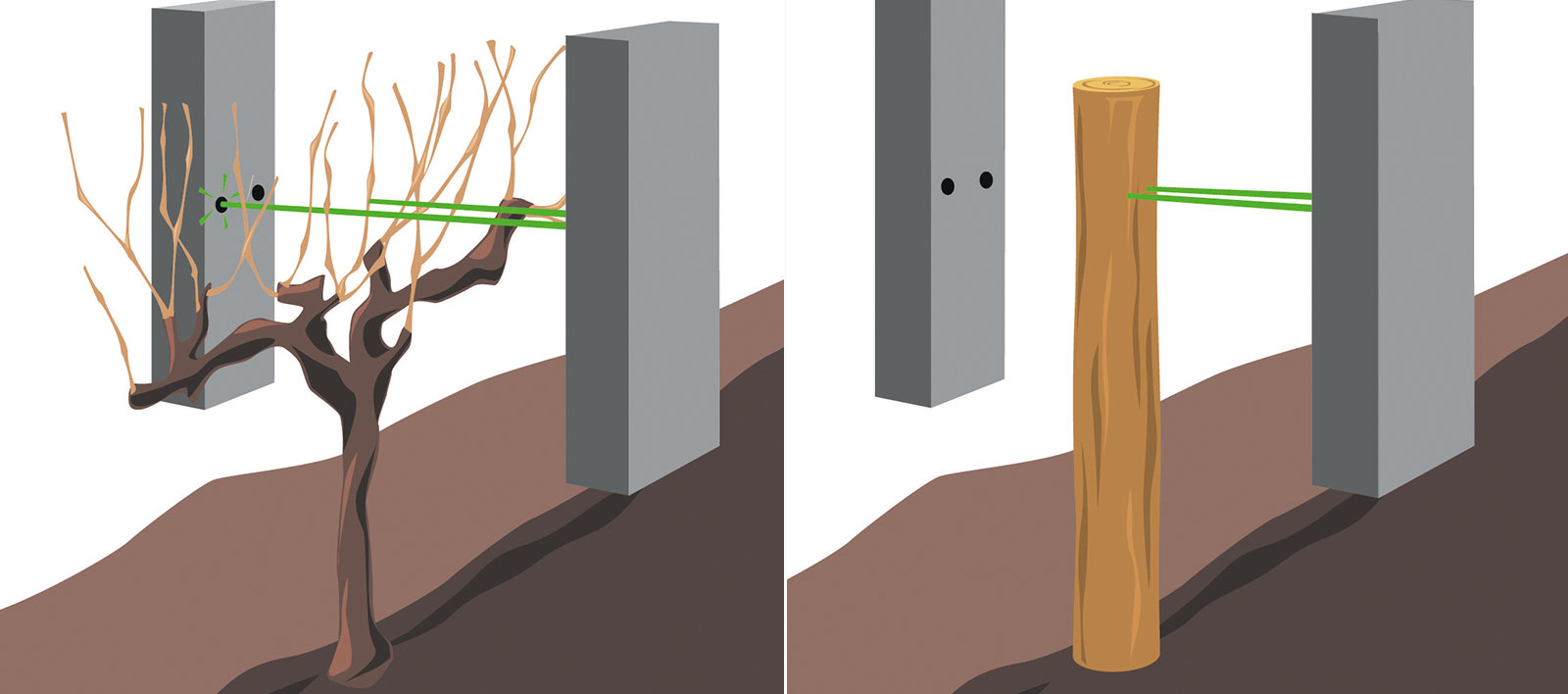

- The artificial vision system (optional) aids the driver and maximizes work performance.

DISCO PLD MULTIVITI at work

Lateral cutter bars (23.6 in high) take out hanging vine shoots. This option saves considerable time when pruning.

Lateral cutter bars available as an option

Driver working comfort: at night, in the rain, or in the sun. Quality work without the stress.

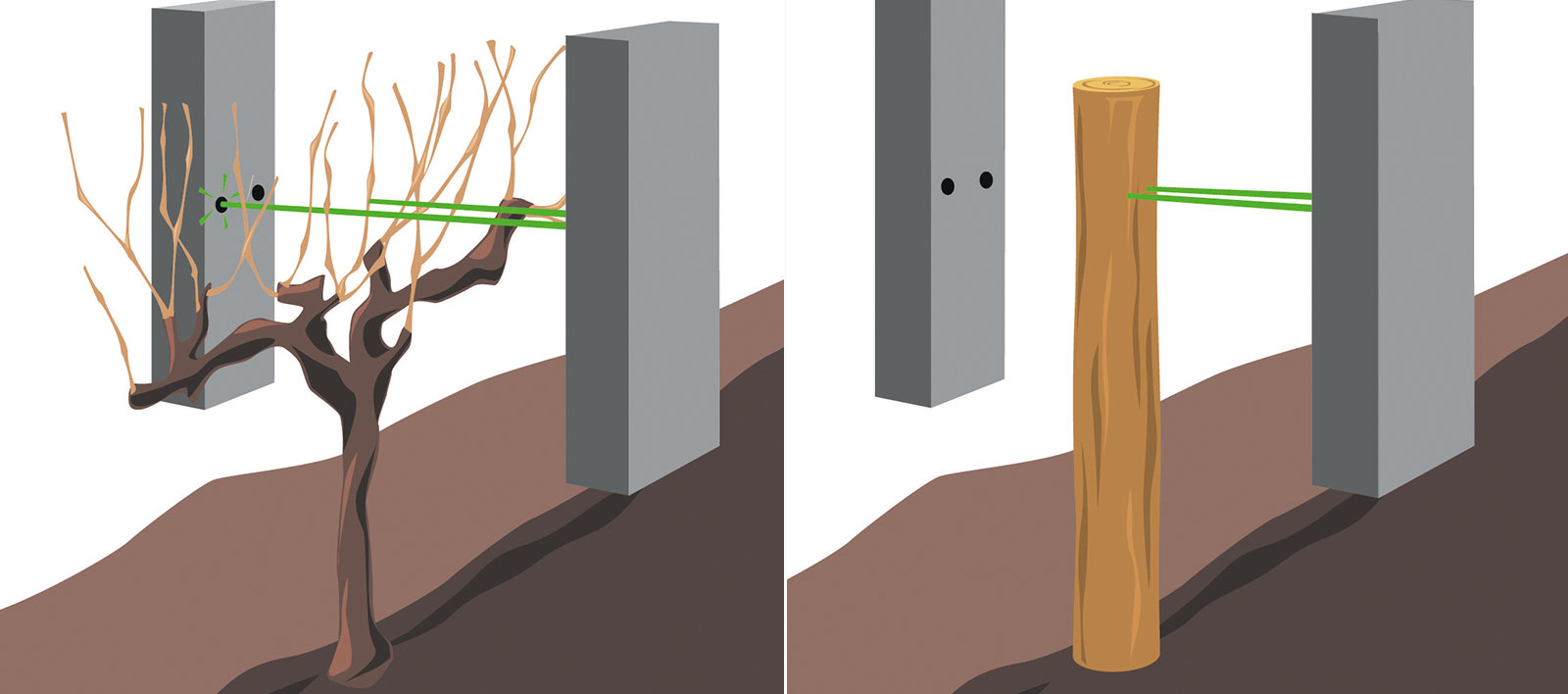

Automatic detection of posts and cordon tracking by machine vision

PELLENC boron steel discs have an extended lifetime and require not sharpening.

Boron steel disc

MULTIVITI coupling.

3 minutes to change tools

Models

|  | |

| TLVP | PLD Multiviti | |

|---|---|---|

| Head with | Long arms | Long arms |

| Number of pairs of bevelled discs with 100 mm spacing | Up to 11 | 5 to 9 pairs |

| Number of pairs of bevelled discs with 50 mm spacing | Up to 21 | 10 to 17 pairs |

| Pairs of 3.9 in long lateral cutting bars | • | • |

| Pairs of 17.7 in diameter lateral discs | • | ─ |

| Coupling | Multifunction arm on Pellenc carrier | Multiviti 20 or 40 frame |

| Manual speed adjustment | From the console | From the console |

| Electric control of all functions | • | • |

| Height and angle settings controlled by hydraulic cylinders | Multifunction arm | Multiviti frame |

| Automatic Vision post detection | • | • |

| Automatic cordon tracking with the vision system | • | • |

| Hydraulic tilting, for Lyre vines | ─ | • |

| Pair of opening wheels | ─ | • |

| Suspension strap slope/safety | ─ | Multiviti frame |

| Delivered on a pallet stand | • | • |

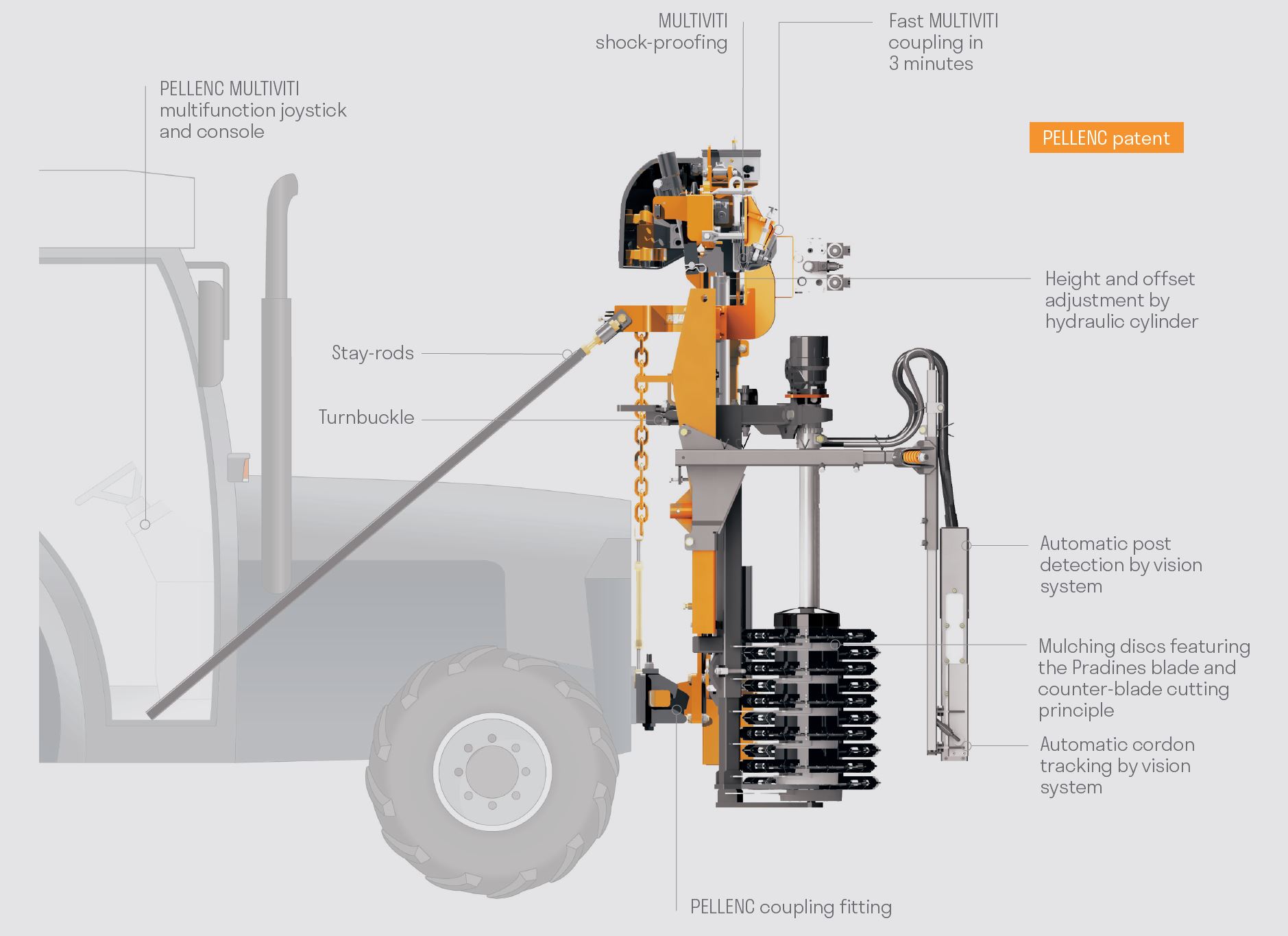

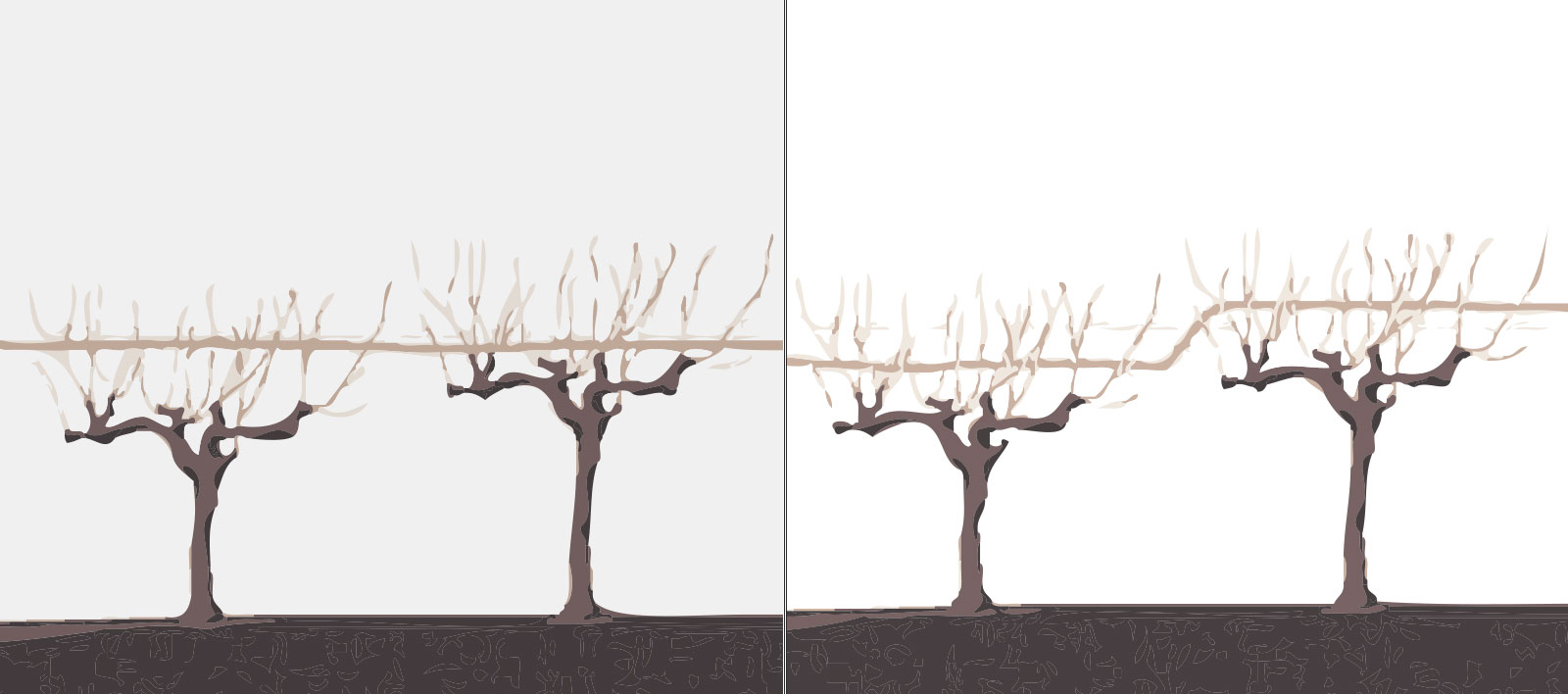

Pruner – VISIO

/in In-row Tractor, Optimum Carrier /by adminx1

Work fast and efficiently, even in dense vegetation with the semi-automatic pruner! Thanks to its VISIO artificial vision technology (optional), this pre-pruner works at high speed, providing cutting and mulching quality superior to disc models.

Coupling the VISIO with the MULTIVITI chassis is fast and simple: 3 minutes are all that are needed to couple and plug in the connexions. The automatic opening around posts makes it possible to comfortably and safely carry out pre-pruning at 3.1 MPH. The retracting safety system with automatic reset of the head optimises the work rate!

We also applaud the low maintenance requirements of the machine.

COST-SAVING

- The mulching discs eliminate wood removal and reduce crushing on the ground.

- Quadrupling the service life of the mulching discs:

reversible and left/right interchangeable. - Low hydraulic requirements: 26.6 to 11.9 gallons/min.

CLEAN CUTTING

- The cutting components require no sharpening.

- Pradines blades with the same cutting quality as pruning shears.

- Better cleaning of the wires and does not damage posts.

OPTIMIZED TIME

- HD (Heavy Duty) for dense vegetation.

- MD (Medium Duty) for average vegetation.

- Working speed of up to 5 mph and up to 60% time saved on pruning.

USER FRIENDLY

- Automatic opening around posts thanks to the artificial vision system (optional).

- You can prune efficiently both day and night.

- Quiet operation.

- Low rotational speed (80 rpm):

no scattering of debris, no sawdust.

Stake detector. Does not damage stakes and vegetation.

Visio: artificial vision system

Forward speed up to 5 MPH.

Working comfort of the driver: when working at night, in the rain, under the sun.

Quality work without the stress.

Quality of work higher than can be achieved with manual operation.

Runs alongside the cordon with the vision system

Greater vine protection.

Exceptional operator comfort.

The result is similar to final pruning thanks to the work of the lower discs.

No more wood removal.

“Marguerite” discs

No more collecting branches on the ground.

Fine mulching.

Long lifespan.

Lateral cutter bars (23.6 in high) cut hanging branches without projections.

Lateral cutter bars available as an option

Get closer with the Precision pruner by combining Visio and lower and lateral discs:

Bottom and lateral discs

“Pruning shear” type cutting.

Unrivalled cutting quality.

Models

|  |  |  |  | |

| TLV MD MULTIVITI | TLV HD MULTIVITI | TCV MULTIVITI | TLV 00 HD TURBO | TLVP | |

|---|---|---|---|---|---|

| Head with | Long arms | Long arms | Short arms | Long arms | Long arms |

| Number of pairs of mulching discs | 5 to 9 | 7 to 9 | 3 to 6 | 7 to 9 | up to 11 |

| Pairs of 23.6 in long lateral cutting bars | ○ | ○ | ─ | ─ | ○ |

| Pairs of 17.7 in diameter lateral discs | ─ | ○ | ─ | ○ | ○ |

| Pair of lower discs | ○ | ○ | ─ | ○ | ○ |

| Coupling | Frontal MULTIVITI | Frontal MULTIVITI | Frontal MULTIVITI | Multifunction arm on Pellenc carrier | Multifunction arm on Pellenc carrier |

| Fast coupling fitting and stay-bars | • | • | • | ─ | ─ |

| Manual speed adjustment | From the console | From the console | From the console | From the console | From the console |

| Electric control of all functions | • | • | • | • | • |

| Height and angle settings controlled by hydraulic cylinders | • | • | • | Carrier | Carrier |

| Automatic Vision post detection | ○ | ○ | ○ | ─ | ○ |

| Automatic cordon tracking with the vision system | ○ | ○ | ○ | ─ | ○ |

| Hydraulic tilting, for Lyre vines | ○ | ○ | ○ | ─ | ─ |

| Pair of opening wheels | ○ | ○ | ○ | ○ | ─ |

| Suspension strap slope/safety | MULTIVITI | MULTIVITI | MULTIVITI | Pellenc multifunction arm | Pellenc multifunction arm |

| Impact-proof cylinder | • | • | • | • | • |

| Delivered on a pallet stand | • | • | • | • | • |

| Independent hydraulic unit | ○ | ○ | ○ | ─ | ─ |

| Hydraulic flow rate (gal/min) | 9.2 | 11.9 | 6.6 | Carrier | Carrier |

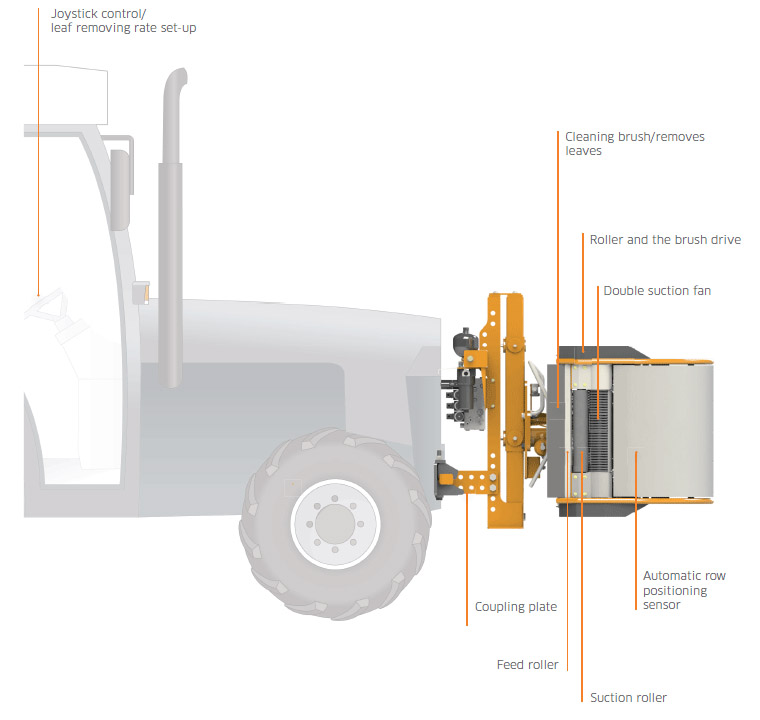

Leaf remover – Full/Half Row

/in In-row Tractor, Optimum Carrier /by adminx1

Quality of manual work, simple and fast.

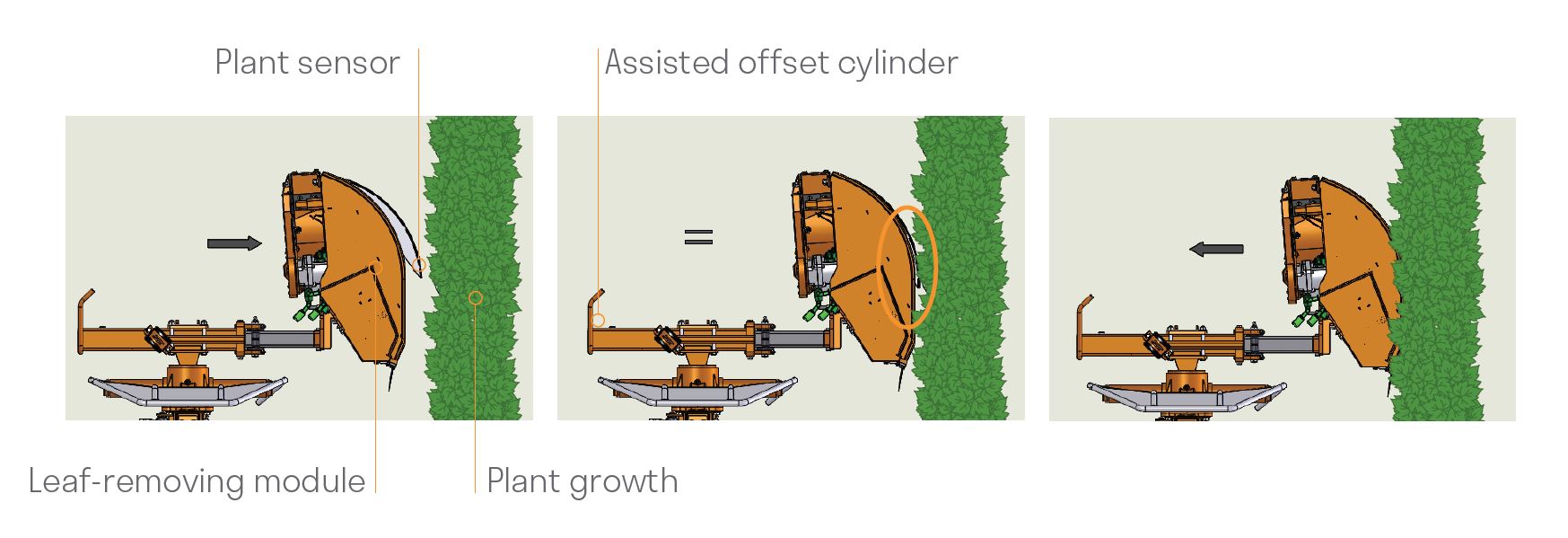

The new leaf remover suits most vineyards and the leaf removal is uniform as if performed by hand. The simple design ensures quick and easy control. The canopy is tracked by a sensor, which automatically manages the tool pressure on the trellising in real time—with no damage to the berries! Adjustments to the amount of leaf being removed is simply adjusted by the turn of a knob inside the cab! The Pellenc Soft-Touch Vineyard Leaf remover is used to effectively and gently pull leaves from the canopy by using the Soft-Touch sensor to automatically manage leaf removal intensity (adjusted with a single knob the cab). Vineyard leaf removal with the Soft-Touch leaf puller provides the same quality as leaf-removal by hand. Available in a half-row reversible model, or a full row model, the Pellenc Soft-touch leaf remover is an excellent tool to mechanize your vineyard management. Watch the video below to see the leaf remover in action and see the difference yourself!

Full row leaf remover on the Optimum carrier

COST-SAVINGS

- High ground speed of up to 2.5 mph.

- Available in a 1/2 row, 1 row, or 2×1/2 row version.

- Suits all vineyards.

- Reduced maintenance cost.

- Low fuel consumption, with reduced power requirements.

The PELLENC leaf remover is very simple to set up and function, and it took no time to learn to use it. Automatic tracking of the plant canopy increases the quality of removing without risk of damage to the berries. The swivel head ensures rapid passage in the headlands and also allows me to adjust the working height to each of my vineyard block. The folding position for transport is truly intelligent, and the visibility and comfort are indisputable. Even better, there is hardly any maintenance thanks to its simple design.

EFFICIENT

- Row tracking makes it possible to work in all types of vineyards with the same leaf removal rate, without damaging the fruiting zone, regardless of the stage of vegetation.

- Automatic safety swing-back mechanism in case of frontal impact.

- Automatic tracking of the plant canopy.

- The rollers catch the leaves without damaging the berries.

Easy and comfortable transportation

USER-FRIENDLY

- Intuitive controls.

- Simple coupling, hydraulic and electrical connections at an accessible height.

- Very good visibility of the row.

- Quiet machine.

- Compact, easy to handle at headlands.

- Reduced overhang and weight.

- Easy to use.

SOFT TOUCH

“Soft Touch” automatic row-tracking system

The suction module is automatically aligned to the plant canopy surface: it moves towards and away from the canopy according to the pressure applied to the sensor.

The Soft Touch system ensures:

- A constant leaf-removal rate (an unbroken swath of leaves on the ground);

- Full protection of the grapes thanks to the responsiveness of the system;

- Unparalleled driving comfort, with jolting eliminated without affecting the leaf-removal rate;

- Override on joystick so the operator can take over when there is no vegetation.

RESULTS

Leaf-removing quality as if done by hand

The row-tracking probe of the SOFT TOUCH leaf remover guarantees total protection of the grape with its wide surface area, and a constant leaf-removal rate with its high responsiveness.

The driver can just focus on driving, Soft Touch does the rest!

MAINTENANCE

Easy cleaning

Washing the module is very easy, with the 2 opening flaps which give direct access to the fan (very little clogging because the leaves do not pass through it) or to the suction zone.

The sensor coming into contact with the vegetation automatically controls the position of the removing head to perfectly follow the plant canopy. Independent tracking of the right/left modules of the 1 complete row leaf remover.

Automatic tracking of the plant canopy

The ½ reversible row leaf remover can work to the left or right of the machine and allows quick rotation at the end of the row.

Modular

The full row leaf remover can also be coupled with the OPTIMUM carrier.

Adaptable on the Optimum carrier

Models

|  | |

| Reversible half row | 1 row | |

|---|---|---|

| Minimum row width – m | 1.5 (5ft) | 1.30 m on the multifunction carrier (4ft 3in) |

| Number of rows | 1/2 | 1 |

| Hydraulic output required – min. | 35 L (9.25 gpm) | 45 L (12 gpm) |

| Coupling system | Front coupling head on tractor | Multifunction carrier |

| Offset settings | • | • |

| Removing height – mm | 380 or 480 | 380 or 480 |

| Electric controls on all functions | • | • |

| Row tracking by sensor | • | • |

| Safety: Hydraulic cut-off | • | • |

| Delivered on a pallet stand | • | • |

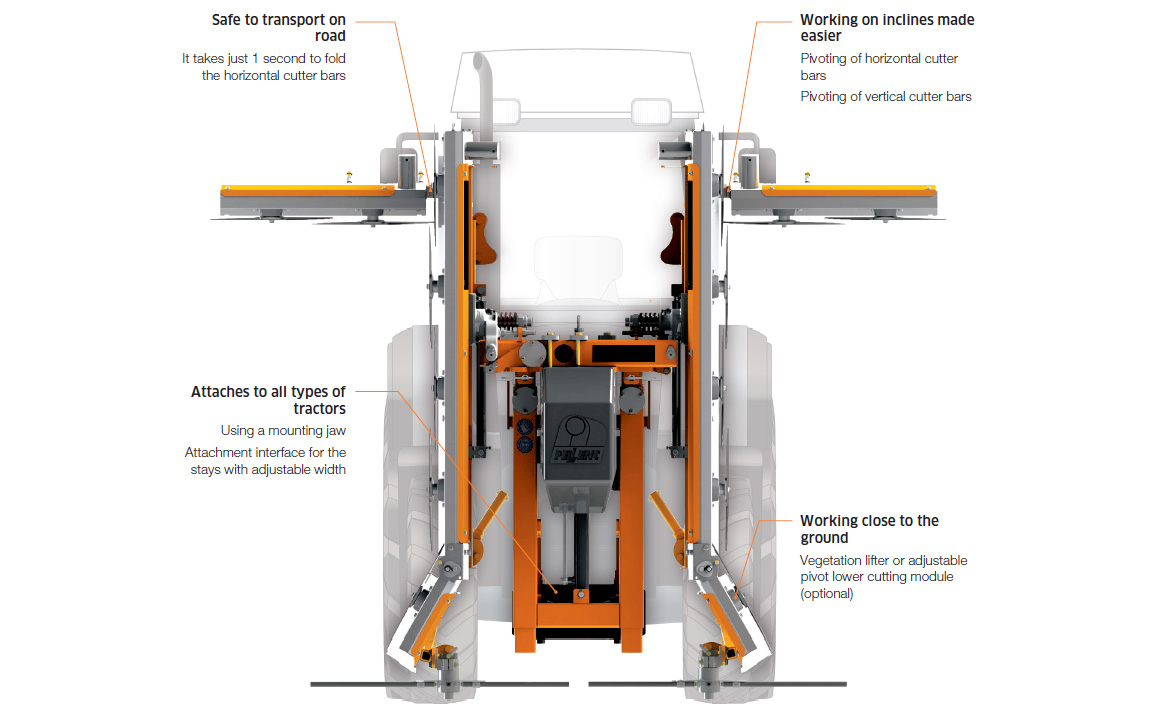

Trimmer – Panorama 2x 1/2 row

/in In-row Tractor /by adminx1

A vision of the future

The PANORAMA trimmer offers great visibility. It is strong and reliable, with two cutting systems: Panorama with reciprocating cutter bars and Panorama with blades. The PANORAMA trimmer gives exceptional visibility along the row.

Cost-effective

- Works without jamming.

- Adjustable pivot lower cutting module (optional).

Comfort

- Unobstructed visibility of the rows.

- Quiet.

- Easy to use.

- No daily maintenance.

Quality

- Set the working width and height for precise work with a single click.

Safety

- Safety mechanism in case of shock, automatic re-setting.

In my opinion, the main strength of the PANORAMA trimmer is its simplicity, both technically and visually. No parts stick out of the chassis and casings and visibility of the cutting elements is excellent. I can work faster while limiting the risk of hanging on a stump. The hydraulic transmission is simple and especially reliable! The precision of steering in the row is very good, the reduced front overhang allows the machine to be positioned accurately relative to the row.

Wide range of settings of the PANORAMA chassis for working effectively in all vineyard configurations.

Large number of settings

Comes standard with a multifunction joystick.

Intuitive controls

1-click control of all functions of the trimmer.

Folding of the horizontal cutting modules without tools for quick and safe road transport.

Folds without tools

Panoramic view of the rows and the trimmer at work.

Panoramic view

Quick pivot vertical cutting bars work efficiently on slopes.

Work efficiently on slopes.

Models

| PANORAMA EC narrow with blades | PANORAMA LC wide blades | PANORAMA EB narrow with reciprocating cutter bars | PANORAMA LB wide with reciprocating cutter bars | |

|---|---|---|---|---|

| Cutting width (in m) | 0.98 to 2.15 (3.21 – 7.05ft) | 1.21 to 2.86 (3.97 – 9.38ft) | 0.89 to 2.03 (2.92 – 6.66ft) | 1.09 to 2.74 (3.57 – 8.99ft) |

| Standard vertical cutter bars | 1.38 m (4.53 ft) with 4 blades | 1.38 m (4.53 ft) with 4 blades | 1.50 m (4.92 ft) BALT 1500 | 1.80 m (5.9 ft) BALT 1800 |

| Option 1 vertical cutter bars | 1.72 m (5.64 ft) with 5 blades | 1.72 m (5.64 ft) with 5 blades | 1.80 m (5.9 ft) BALT 1800 | 1.50 m (4.92 ft) BALT 1500 |

| Horizontal cutting bars | 0.73 m (2.4 ft) with 2 blades | 0.73 m (2.4 ft) with 2 blades | 0.90 m (2.95 ft) BALT 900 | 0.90 m (2.95 ft) BALT 900 |

| Cut-off on impact ensures safety at all times | • | • | • | • |

| Control joystick | • | • | • | • |

| Height and hydraulic spacing adjustment hydraulique | • | • | • | • |

| Manual height adjustment of horizontal bars | • | • | • | • |

| Hydraulic height adjustment of horizontal cutter bars | ○ | ○ | ○ | ○ |

| Mounting plate and stay-rod | • | • | • | • |

| Delivery on a pallet stand | • | • | • | • |

| Working close to the ground (optional) | Fifth lower cutting module (fixed or pivoting) | Fifth lower cutting module (fixed or pivoting) | Vegetation lifter | Vegetation lifter |

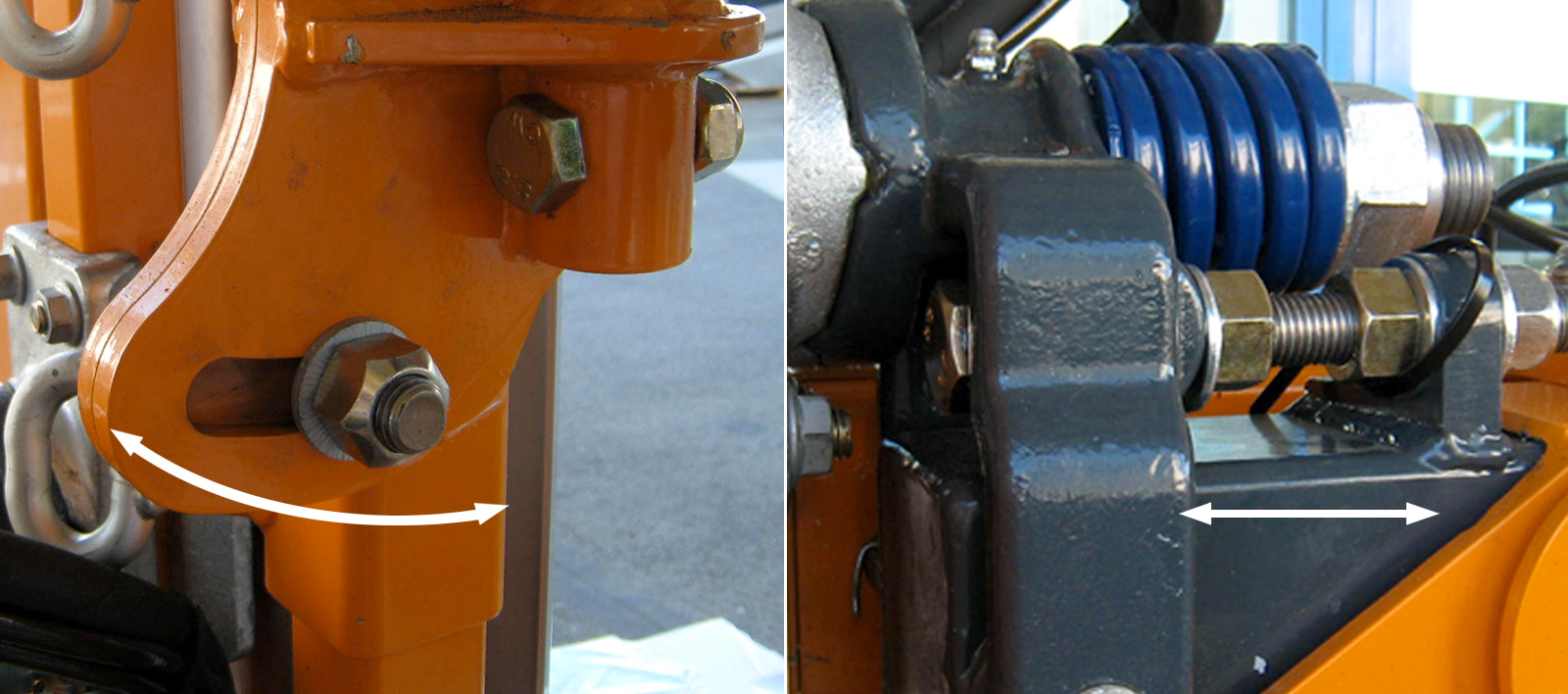

Trimmer – Multiviti

/in In-row Tractor, Optimum Carrier /by adminx1

The PELLENC trimmer with blades offers performance with reduced maintenance: trim up to 6 mph with no fouling!

As these cutter bars are modular, they adapt to suit the requirements of all vine growers and vineyard configurations.

CLEAN CUTTING

- High rotational speed of the blades: clean cutting at all plant growth stages.

- Work without fouling.

- Adjustable pivot, lower cutting module (optional).

- Pivoting vegetation lifter available as an option.

- Sylvose cutting module available as an option.

SPEED

- High working speed: up to 6 mph.

USER-FRIENDLY

- Quiet.

- Easy to use.

- No daily maintenance.

- Horizontal folding of modules without tools for road transport (Panorama).

SAFETY

- Impact-proof design

The trimmer on a MULTIVITI chassis offers the advantage of being controlled by the Pellenc MULTIVITI joystick, which I find ergonomic and easy to use. The drive is simple and robust, and the machine requires little power and maintenance. I am pleased to say that thanks to the Mutiviti trimmer I save time in the vineyard as well as in the workshop!

Pellenc Blades

Change blades in one minute.

Very little fouling.

High rotation speed for clean cutting.

Impact-Proof Design

Tension spring safety devices ensure retraction of the cutting elements.

Tilting Lower Cutting Module

Cut lower areas of the canopy at an angle with optional module.

Hydraulic and electrical connections are made rapidly and are located at shoulder height.

Quick coupling in just 3 minutes

Automatic tool recognition for the MULTIVITI Joystick.

Comes standard with a multifunction joystick.

Intuitive controls

1-click control of all functions of the trimmer.

Models

| MULTIVITI C (Blades) | MULTIVITI B (Reciprocating cutter bars) | |

|---|---|---|

| Cutting width (in m) | 0.3 to 1 (1 – 3.28ft) | 0.3 to 1.2 (1 – 3.94ft) |

| Standard vertical cutter bars | 1.38 m with 4 blades (4.53 ft) | 1.8 m (5.9 ft) BALT 1800 |

| Option 1 vertical cutter bars | 1.72 m with 5 blades (5.64 ft) | 1.5 m (4.92 ft) BALT 1500 |

| Horizontal cutting bars | 1.05 m with 3 blades (3.44 ft) | 0.7 m: 1 Evoludisc 700 satellite (2.3 ft) |

| Optional horizontal cutting bar | – | 1.2 m: 2 Evoludisc 600 satellites (3.94 ft) |

| Cut-off on impact ensures safety at all times | • | • |

| Control joystick | • | • |

| Height and hydraulic offset adjustment | • | • |

| Manual height adjustment of the horizontal cutting bar | – | • |

| Hydraulic height adjustment of the horizontal cutting bar | • | – |

| Mounting plate and stay-rod | • | • |

| Delivery on a pallet stand | • | • |

| Working close to the ground (optional) | Fifth lower cutting module (fixed or pivoting) | – |

Wire Lifter

/in In-row Tractor, Optimum Carrier /by adminx1

Lift, attach and trim all at once!

Perform three operations in one run, with a single tool — this is made possible by the PELLENC trellising machine! Your vines have a uniform canopy, so grape clusters are better exposed to spray treatments. Lifting the leaves improves photosynthesis, ensuring optimal maturity of the berries.

Wide range of clips available

MULTIFUNCTION

- Three operations at once: wire lifting, trimming, and trellising.

EFFICIENT

- The operator controls the positioning of the clips.

- Formation of a uniform, wind-resistant canopy.

- Working speed: 2.5 to 3 mph, even in dense plant growth, i.e. 2.5 acres/hour (in 8.2 ft).

USER-FRIENDLY

- Very quiet tool.

- Low hydraulic requirement: 6.6 gallons/min.

- Excellent ease of handling—installed on the trellis with a single click (automatically picks up the pair of lifting wires at the beginning of the row).

- Use at different stages of growth.

- Several types of lifting wires can be used: steel and nylon.

ECO-FRIENDLY

- PELLENC clips are made from photodegradable and food-grade material.

- Carry out three operations all at once: limits CO2 emissions and preserves the root system.

We use our lifting machine on the 8490 carrier, which we also use for pre-pruning, ploughing and harvesting. This arrangement allows us to work faster and optimize the amortization of the lifter and the carrier. The rapid work rate allows us to carry out lifting on each plot at the perfect time and later than with manual lifting, this allows us to avoid one top trimming job each year.

THE TRELLISING MACHINE OPERATES ON THREE PRINCIPLES:

- Simplicity: it uses the pair of lifting wires permanently installed on the trellising from one end of the row to the other.

- Cost saving: the system can be reused each year.

- Safe: by lifting two wires, the trellising machine carries the vegetation in an upward motion to form a plant canopy that is uniform and wind resistant.

PELLENC range of clips

PELLENC-manufactured clips ensure the proper functioning of the PELLENC trellising machine. Designed for use with our trellising machine with widths adapted to different types of vines. Each model has different tensile strengths based on the thickness of the canopy or its use (first lifting). The clips are made from photodegradable and food-grade material.

Ultra narrow clip (18mm)

First lift clip (31mm)

Narrow clip (31mm)

Wide clip (57mm)

The trellising machine works with all types of posts except those equipped with a T bar larger than 6 inches. Quality of posts, installation, and tension of lifting wires are essential factors for the proper mechanization of vine lifting and attaching trellis wires. Three types of wire are possible: galvanized non-steel, galvanized steel, and nylon. The galvanized steel wires No. 13 and No. 16 (2 mm to 2.7 mm depending on plant growth) produce the best results. Using suitable lifting wires is a requirement for proper mechanized lifting and trellising of the vine.

Trellising recommendations

Choice of lifting wires

Preparation for “entry into the rows”

By manually engaging the vegetation between the wires for the first 10-15 feet of the row, it is easier for the wire lifter to enter into the rows and for the wires to be caught automatically (mainly for vineyards with dense vegetation).

Lifting wire tension

Several parameters: length of rows, vigor and density of plant growth, type of wire.

Optimal set-up: the lifting wires touch the ground around 30 to 50 feet from the head post.

In other cases, we recommend you install fastening stirrups and tension chains on the anchoring posts in order to determine in use, the best thread tension, placing the lifting wire tensioners at the end of the rows.

Importance of cultivation techniques

The ease and quality of lifting depends on the grape variety (naturally upright or falling) and the cultivation techniques of the vineyard. We recommend “cordon” or “flat tying” for best results.

Models

|

| |

| MULTIVITI | On Optimum | |

|---|---|---|

| Trimming attachment | • | • |

| Coupling | In-Row Tractor w/Multiviti Arm | Multifunction arm |

| Fast coupling fitting and stay-rods | • | ─ |

| Stapling mechanism | • | • |

| Electric control of all functions | • | • |

| Height and offset adjustment by hydraulic cylinders | • | PELLENC multifunction arm |

| Two upper and lower vegetation feeders | • | • |

| Delivered on a pallet stand | • | • |

| Hydraulic requirement (l/min) | 25 l/min at 180 bars (6.6 gal/min @ 2610psi) | Carrier/Tractor |

| Wire holding kit | ○ | ○ |

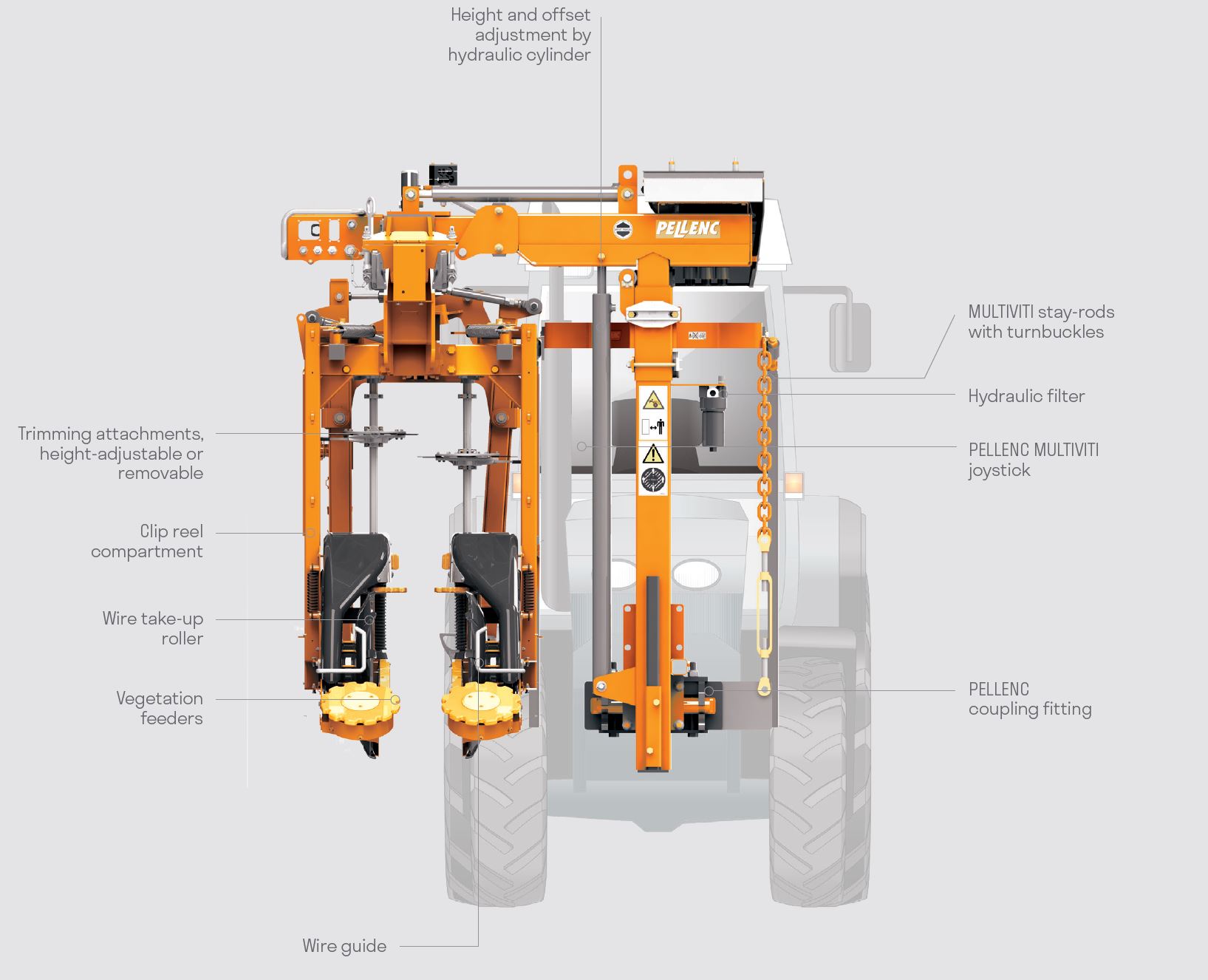

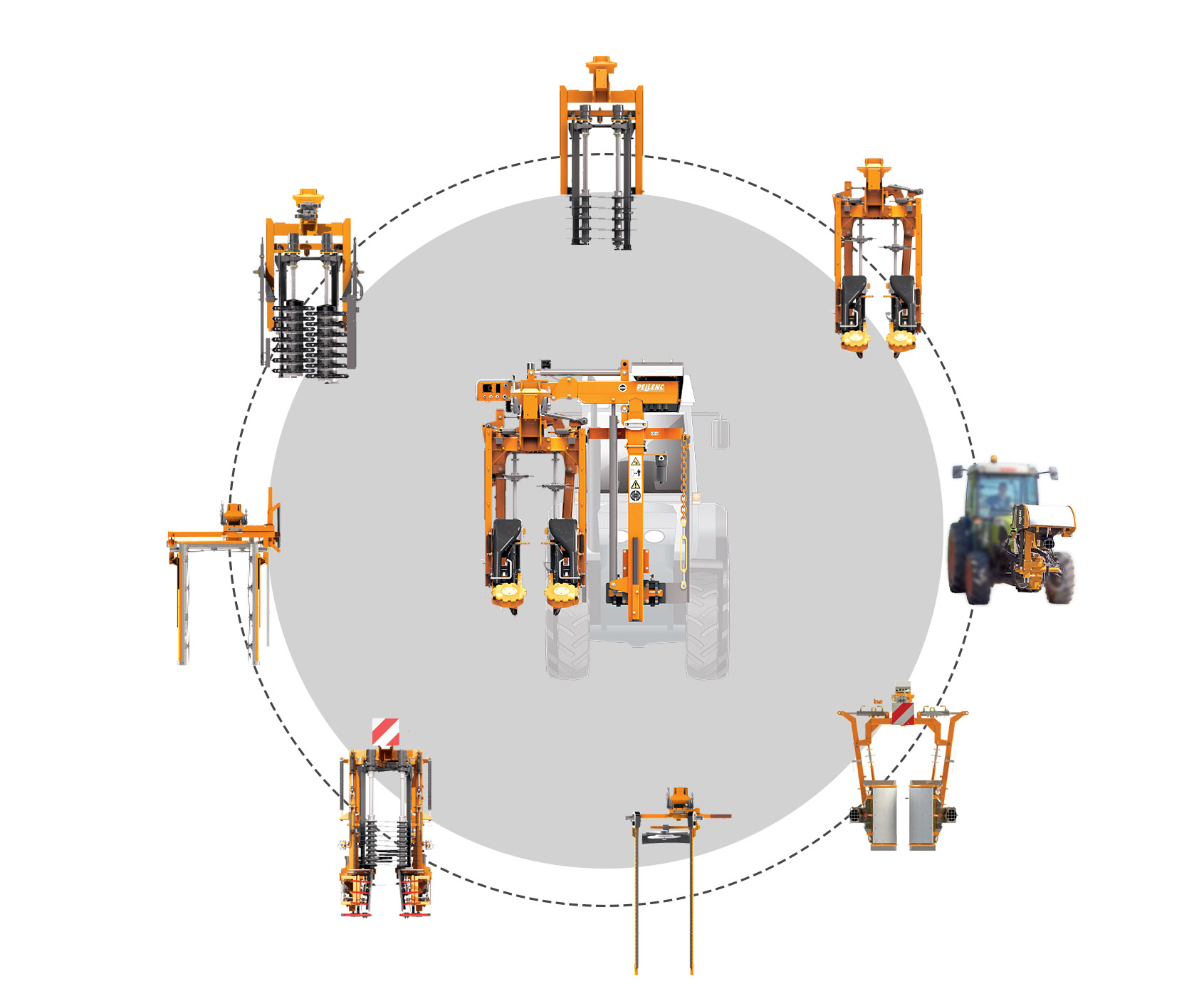

Multifunction: Multiviti frame

/in In-row Tractor /by adminx1

Use Pellenc vineyard tools with your in-row tractor!

With MULTIVITI, you can hitch all PELLENC vineyard tools onto the same chassis in just 3 minutes! The range includes three chassis: MULTIVITI 20 and 40 chassis on an in-row tractor, and a 1 or 2-row MULTIVITI straddle chassis on a straddle tractor.

MULTIFUNCTION

- Use PELLENC year-round mechanized vineyard tools with Multiviti Frame.

- Works with other equipment.

- Change tools in record time.

Get a Quote

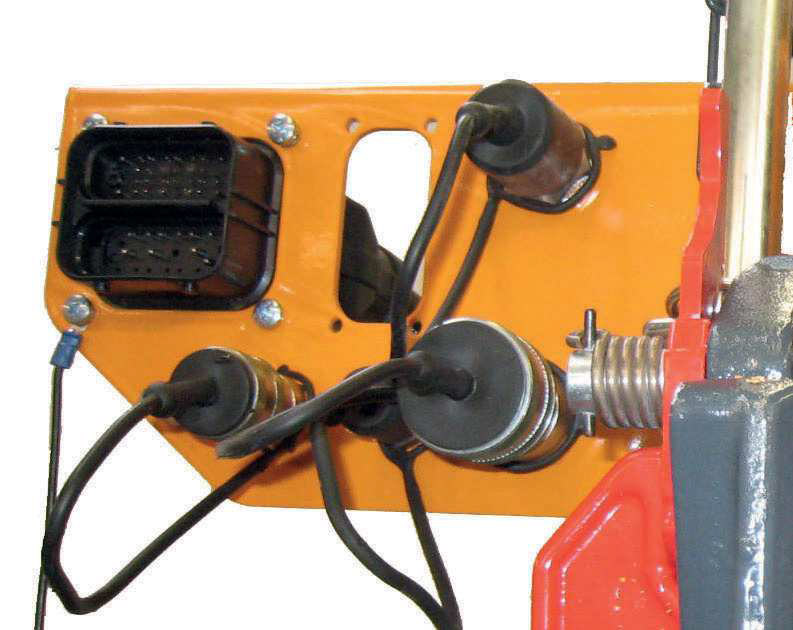

USER-FRIENDLY

- All the settings are within reach.

- The ergonomic, backlit PELLENC MULTIVITI joystick and screen incorporate all the functions and self-diagnostics of each tool coupled.

- A tool with exceptional work stability.

SAFE

- A single person can couple and uncouple tools.

- Coupling plate with safety pin.

- Simple and intuitive connection:

> Three push-pull connectors

> Two electrical sockets - MULTIVITI 20, 40, or 1- and 2-row straddle tractor:

Four versions available for working comfortably and safely in all situations.

We use our MULTIVITI chassis with a VISIO HD pre-pruner (250 hectares/year) or a PELLENC wire lifter (50 hectares per year). We were interested in the quick change capability of the tool. We are really pleased with the ease and speed of change in actual use: only a mechanical key to open, two hydraulic push-pulls, and an electrical outlet to plug in! The compact chassis allows us to perform all kinds of work in the vineyard without removing the frame or snagging the foliage. The time saved is significant, especially during periods of high activity.

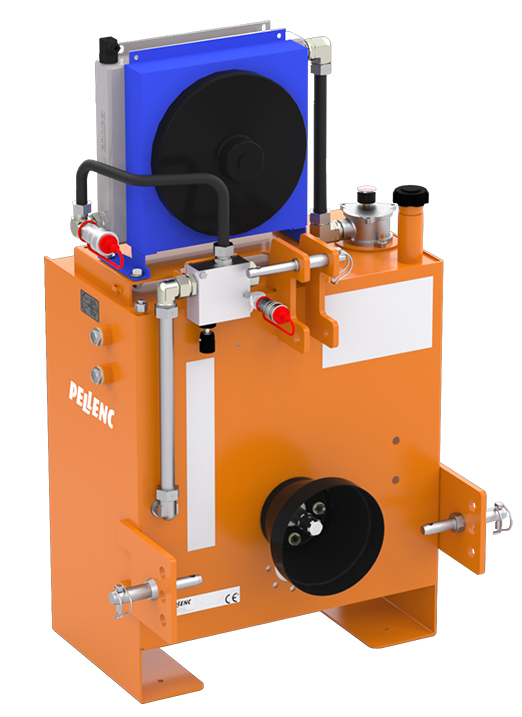

HYDRAULIC UNIT V2

Pellenc Multiviti hydraulic unit

More power without changing the tractor:

- 53 L capacity (14 gal)

- Flow rate: up to 20 gal/min

- Flow controller

- Single hydraulic pump

- Integrated oil cooler

- Optional central or lateral weight holder

Multiviti tool range

Simple and economical

Disco pre-pruner

> Working speed: up to 3 mph, even in dense vegetation

> The extremely resistant boron steel discs do not require sharpening.

> Clean cutting of vine shoots

> Automatic opening around posts thanks to an artificial visioning system (optional)

Power and speed, both day and night

Visio Pre-pruner

> Working speed: up to 5 mph

> Mulching discs eliminate wood removal.

> Pradines blades provide the same cutting quality as pruning shears.

> Automatic opening around posts thanks to an artificial visioning system (optional)

Reduce costs and pruning time, without fatigue

The Precision Pruner

> Working speed: up to 2 mph, day or night.

> Reduces pruning time by up to 90%

> Cordon tracking by vision system: quality, comfort, and fatigue-free.

> Intensive daily output.

Lift, trim, and trellis wires in a single run

Wire lifter

> Working speed: 2.5 to 3 mph

> An unbeatable tool for vines with dense vegetation.

> The canopy is uniform, wind-resistant and comparable with canopies that are created by manual work.

> Wide range of ties.

Safely carry out “Pruning shear” like cuts

Trimmer with Cutter Bars

> Working speed: up to 5 mph.

> Sturdy and quiet with no scattering of debris.

> Reciprocating self-cleaning blades.

> Cut branches of any diameter.

> Safety mechanism in case of shock.

Rotary cutting without clogging

Trimmer with Blades

> Working speed: up to 6 mph.

> Adjustable pivoting lower cutting module.

> Impact-proof design.

> Blades with low sap accumulation.

3171 Guerneville Road Santa Rosa, CA 95401 United States

Tel. +1 (707) 568 7286

Email : information@pellencus.com

This site uses cookies. By continuing to browse the site, you are agreeing to our use of cookies.

AcceptLearn moreCookie and Privacy Settings

We may request cookies to be set on your device. We use cookies to let us know when you visit our websites, how you interact with us, to enrich your user experience, and to customize your relationship with our website.

Click on the different category headings to find out more. You can also change some of your preferences. Note that blocking some types of cookies may impact your experience on our websites and the services we are able to offer.

These cookies are strictly necessary to provide you with services available through our website and to use some of its features.

Because these cookies are strictly necessary to deliver the website, refuseing them will have impact how our site functions. You always can block or delete cookies by changing your browser settings and force blocking all cookies on this website. But this will always prompt you to accept/refuse cookies when revisiting our site.

We fully respect if you want to refuse cookies but to avoid asking you again and again kindly allow us to store a cookie for that. You are free to opt out any time or opt in for other cookies to get a better experience. If you refuse cookies we will remove all set cookies in our domain.

We provide you with a list of stored cookies on your computer in our domain so you can check what we stored. Due to security reasons we are not able to show or modify cookies from other domains. You can check these in your browser security settings.

These cookies collect information that is used either in aggregate form to help us understand how our website is being used or how effective our marketing campaigns are, or to help us customize our website and application for you in order to enhance your experience.

If you do not want that we track your visit to our site you can disable tracking in your browser here:

We also use different external services like Google Webfonts, Google Maps, and external Video providers. Since these providers may collect personal data like your IP address we allow you to block them here. Please be aware that this might heavily reduce the functionality and appearance of our site. Changes will take effect once you reload the page.

Google Webfont Settings:

Google Map Settings:

Google reCaptcha Settings:

Vimeo and Youtube video embeds:

The following cookies are also needed - You can choose if you want to allow them:

You can read about our cookies and privacy settings in detail on our Privacy Policy Page.

Privacy Policy