Wire Lifter

/in In-row Tractor, Optimum Carrier /by adminx1

Lift, attach and trim all at once!

Perform three operations in one run, with a single tool — this is made possible by the PELLENC trellising machine! Your vines have a uniform canopy, so grape clusters are better exposed to spray treatments. Lifting the leaves improves photosynthesis, ensuring optimal maturity of the berries.

Wide range of clips available

MULTIFUNCTION

- Three operations at once: wire lifting, trimming, and trellising.

EFFICIENT

- The operator controls the positioning of the clips.

- Formation of a uniform, wind-resistant canopy.

- Working speed: 2.5 to 3 mph, even in dense plant growth, i.e. 2.5 acres/hour (in 8.2 ft).

USER-FRIENDLY

- Very quiet tool.

- Low hydraulic requirement: 6.6 gallons/min.

- Excellent ease of handling—installed on the trellis with a single click (automatically picks up the pair of lifting wires at the beginning of the row).

- Use at different stages of growth.

- Several types of lifting wires can be used: steel and nylon.

ECO-FRIENDLY

- PELLENC clips are made from photodegradable and food-grade material.

- Carry out three operations all at once: limits CO2 emissions and preserves the root system.

We use our lifting machine on the 8490 carrier, which we also use for pre-pruning, ploughing and harvesting. This arrangement allows us to work faster and optimize the amortization of the lifter and the carrier. The rapid work rate allows us to carry out lifting on each plot at the perfect time and later than with manual lifting, this allows us to avoid one top trimming job each year.

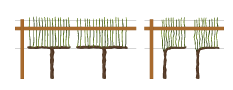

THE TRELLISING MACHINE OPERATES ON THREE PRINCIPLES:

- Simplicity: it uses the pair of lifting wires permanently installed on the trellising from one end of the row to the other.

- Cost saving: the system can be reused each year.

- Safe: by lifting two wires, the trellising machine carries the vegetation in an upward motion to form a plant canopy that is uniform and wind resistant.

PELLENC range of clips

PELLENC-manufactured clips ensure the proper functioning of the PELLENC trellising machine. Designed for use with our trellising machine with widths adapted to different types of vines. Each model has different tensile strengths based on the thickness of the canopy or its use (first lifting). The clips are made from photodegradable and food-grade material.

Ultra narrow clip (18mm)

First lift clip (31mm)

Narrow clip (31mm)

Wide clip (57mm)

The trellising machine works with all types of posts except those equipped with a T bar larger than 6 inches. Quality of posts, installation, and tension of lifting wires are essential factors for the proper mechanization of vine lifting and attaching trellis wires. Three types of wire are possible: galvanized non-steel, galvanized steel, and nylon. The galvanized steel wires No. 13 and No. 16 (2 mm to 2.7 mm depending on plant growth) produce the best results. Using suitable lifting wires is a requirement for proper mechanized lifting and trellising of the vine.

Trellising recommendations

Choice of lifting wires

Preparation for “entry into the rows”

By manually engaging the vegetation between the wires for the first 10-15 feet of the row, it is easier for the wire lifter to enter into the rows and for the wires to be caught automatically (mainly for vineyards with dense vegetation).

Lifting wire tension

Several parameters: length of rows, vigor and density of plant growth, type of wire.

Optimal set-up: the lifting wires touch the ground around 30 to 50 feet from the head post.

In other cases, we recommend you install fastening stirrups and tension chains on the anchoring posts in order to determine in use, the best thread tension, placing the lifting wire tensioners at the end of the rows.

Importance of cultivation techniques

The ease and quality of lifting depends on the grape variety (naturally upright or falling) and the cultivation techniques of the vineyard. We recommend “cordon” or “flat tying” for best results.

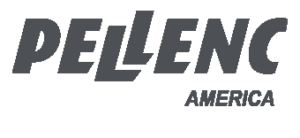

Models

|

| |

| MULTIVITI | On Optimum | |

|---|---|---|

| Trimming attachment | • | • |

| Coupling | In-Row Tractor w/Multiviti Arm | Multifunction arm |

| Fast coupling fitting and stay-rods | • | ─ |

| Stapling mechanism | • | • |

| Electric control of all functions | • | • |

| Height and offset adjustment by hydraulic cylinders | • | PELLENC multifunction arm |

| Two upper and lower vegetation feeders | • | • |

| Delivered on a pallet stand | • | • |

| Hydraulic requirement (l/min) | 25 l/min at 180 bars (6.6 gal/min @ 2610psi) | Carrier/Tractor |

| Wire holding kit | ○ | ○ |

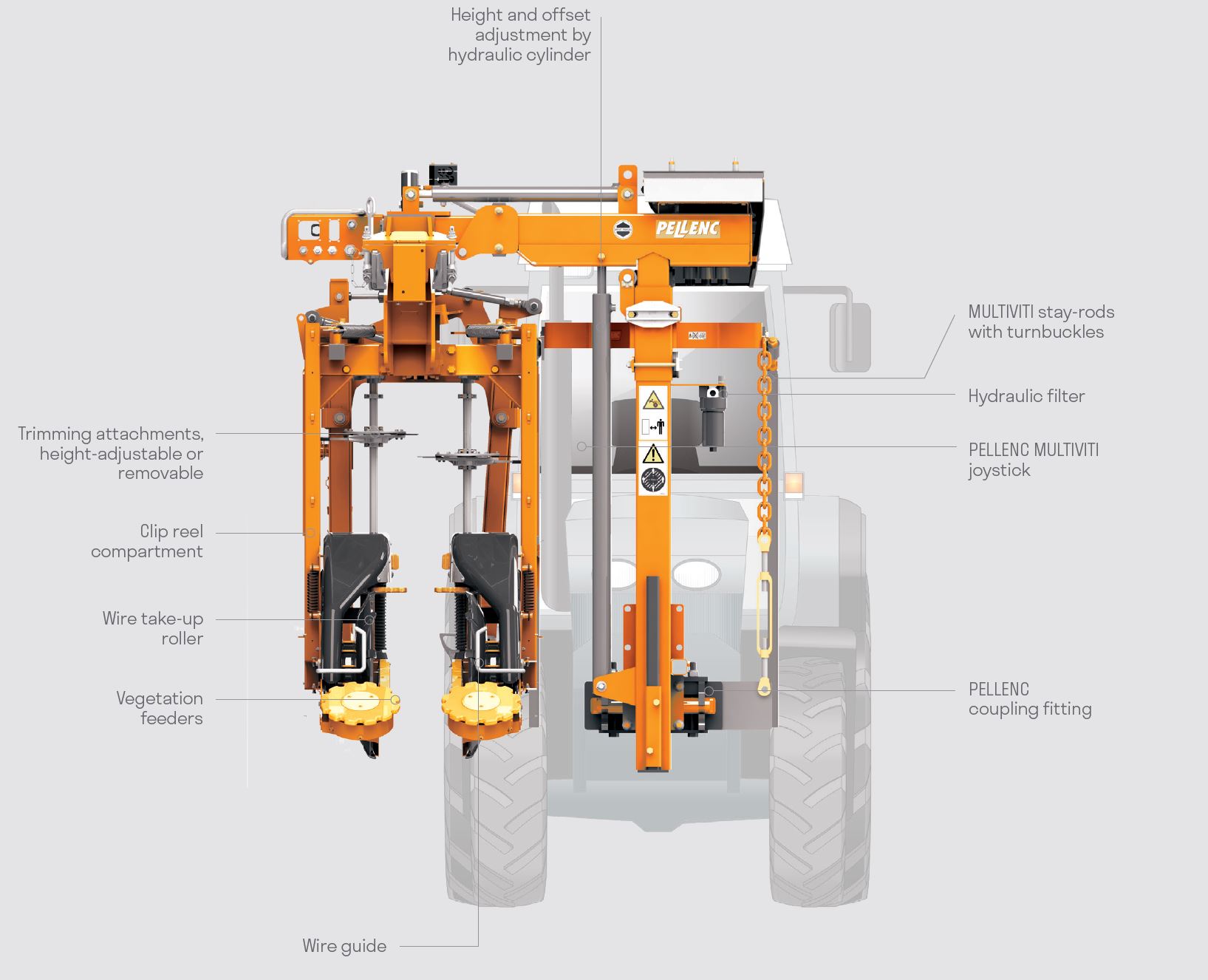

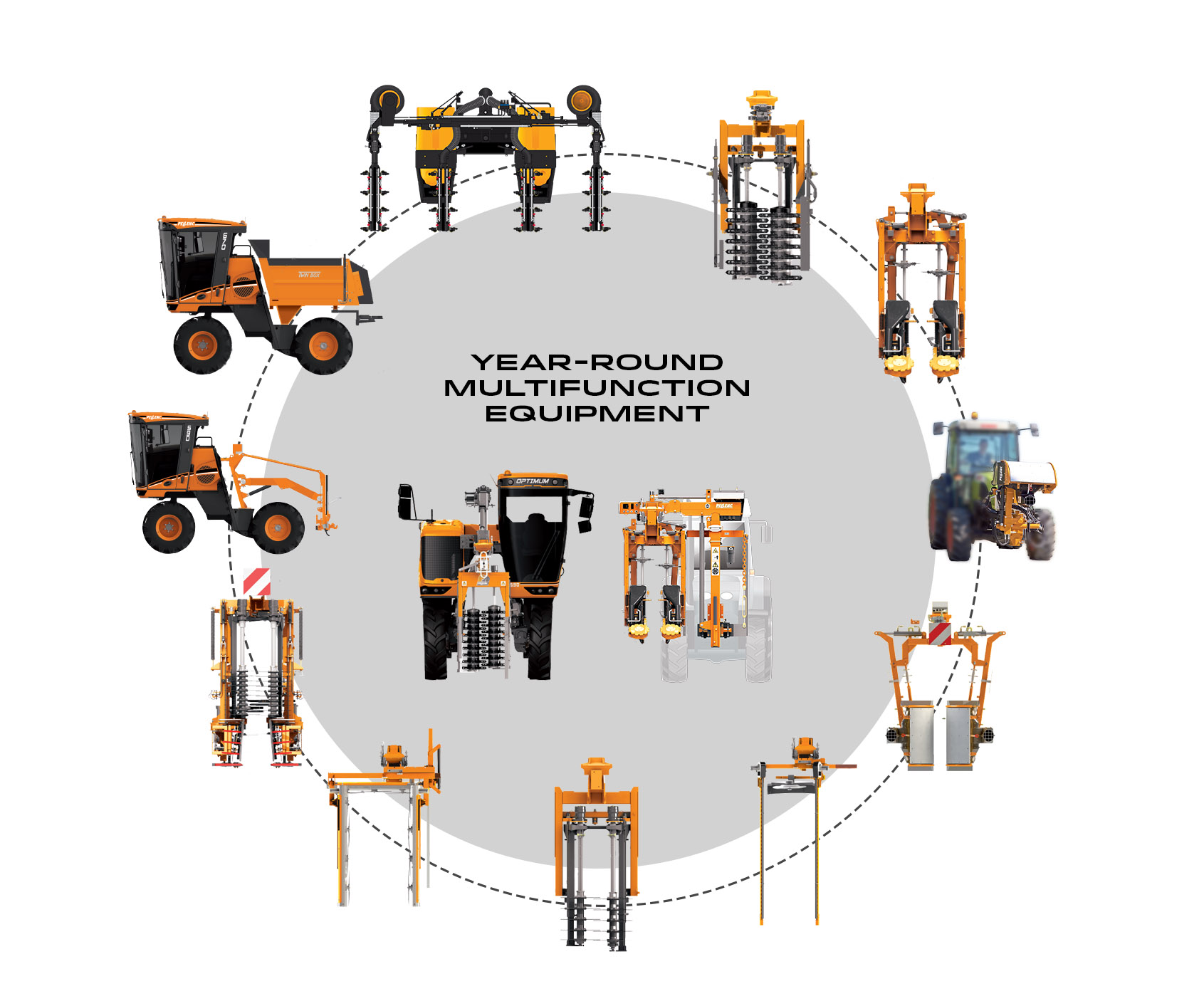

Multifunction: Front arm and weight holder

/in Optimum Carrier /by adminx1

Quick Change

- A single connection point for the hydraulic push-pulls and electrical outlets at shoulder height (same as with the MULTIVITI chassis).

- Automatic recognition of coupled tools.

- Automatic reallocation of commands on the joystick and the EASY TOUCH Multifunction console for the tools connected.

Accessible to all

- Automatic adaptation of the rotation speed of the tool coupled to the front arm according to the carrier’s forward speed.

- Numerical indications of arm length visible from the cab.

- Optional: hydraulic adjustment of the length of the arm from the cab.

Safe

- Road approval with PELLENC multifunction tools.

- Good visibility on the road and while working.

- Optimum stability on gradients and slopes with the weight holder and a low center of gravity.

22 of our 26 PELLENC carriers are equipped with front arm/weight holders for carrying out jobs such as thinning of shoots, leaf stripping, and sinking posts as a service provider. As such, we optimize the amortization of our carriers, each of which is in use from 700 to 800 hours annually. Using a carrier for this type of work improves the performance and the quality of our work—it is a win-win situation for our customers and for us!

Front Arm attachment:

Take advantage of the front arm attachment for Optimum series tractors. The Multifunction arm attaches conveniently to the quick monocoupler allowing you to power any Pellenc Multiviti equipment.

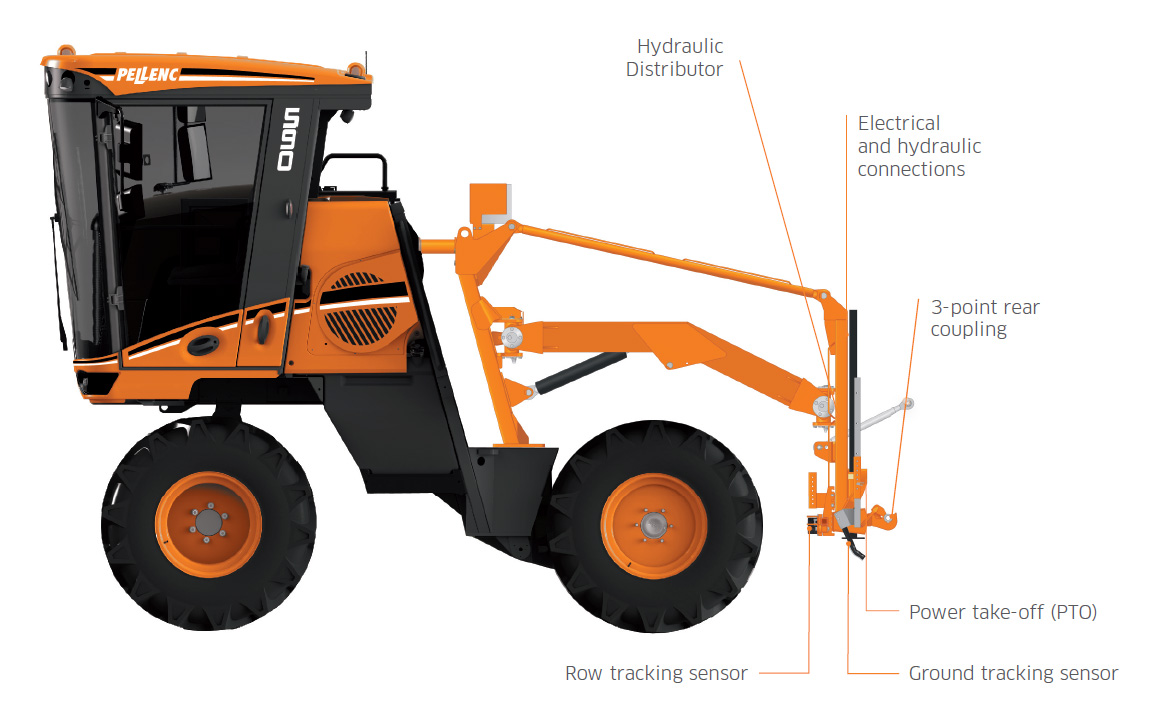

Twin Row 3-Point – TR3

/in Optimum Carrier /by adminx1

Combined Multifunction

THE ONLY CARRIER ON THE MARKET CAPABLE OF WORKING TWO FULL ROWS WITH TWO DIFFERENT TOOLS SIMULTANEOUSLY

The growing concerns of vine growers about the profitability of their farms, particularly in light of restrictions on herbicides, climate change, new requirements regarding pesticides, and expanding acreage are what led us to develop COMBINED MULTIFUNCTION.

The PELLENC multifunction carrier is equipped with mechanical, electrical, and hydraulic coupling systems for the quick fitting of one tool at the front of the multifunction arm and another at the rear, so that two full rows can be worked at once.

SIMPLE TO USE

- Adjustment of the position of the tools for automatic row entry.

- Automatic centering of the tools in the rows (sensors).

- Automation: ground tracking, slope correction and centering at the end of the row.

ECONOMICAL

- Work two rows simultaneously and at high speed.

- Makes it possible to do two jobs at once.

TECHNICAL SPECS

- 3-point hitching on Pellenc carrier.

- 2 tool holder arms equipped with universal couplings.

- 3-point rear tractor-type couplings.

- Hydraulic arm spacing in the row.

- Arm height adjustment (1.10 m / 43 inch travel).

- Automatic centering of arms.

- Setting of rows spacing from the cab control panel.

- Ground tracking and auto-leveling.

- 2 hydraulic P.T.O.

- 3 dual-acting hydraulic distributors.

Spreader – Twin Box

/in Optimum Carrier /by adminx1

The Twin Box 2-row spreader is multifunctional and multi-purpose. With its large on-board capacity, you can change and adapt your type of application simply and quickly (soil, manure, fertilizer, powder, bark, additives, etc.).

Cost effective

- 2 rows spread at the same time.

- Carry up to 3.4 m3 (120ft3) of product.

- Working speed based on hectare flow rate.

- Multipurpose: manure, compost, fertilizer, earth and powders.

Quality

- Precision spreading.

- Spreading is done by chain and bar conveyor, or rubber conveyor or rotors.

Comfort

- Ergonomic steering on the PELLENC carrier.

Environment

- Wheels centred in the row which limits pressure on the root system.

The work rate is perfect for me. I work at 8km/h covering 7 rows* with fertilizer or 2 rows with manure. This efficiency allows me to find extra time and do a few spreading jobs as a service. Mounting on the carrier allows increased loading capacity compared to towed models, so I spend less time on the road and more in the field.

Models

| TWIN BOX | |

|---|---|

| Chassis | Twin feed boxes |

| Box volume – m3 | 2 x 1.7 (2 x 449 gal) |

| Number of rows worked | Two (or more with the extra wide spreading option) |

| Product transportation | Chain and bar conveyor |

| Acre rate control | Conveyor speed variation controlled by hydraulic reducer |

| Rear cover opening | Hydraulics with mechanical memory |

| Conveyor speed control | LH/RH independent |

| Feed box loading protection | • |

| Ladder | • |

| Stands | • |

| Optional compost/manure kit (horizontal rotors) | ○ |

| Rubber feed conveyor kit + reduction motor (low concentration per acre) | ○ |

| Extra wide spreader kit | ○ |

| Quick coupler kit | ○ |

3171 Guerneville Road Santa Rosa, CA 95401 United States

Tel. +1 (707) 568 7286

Email : information@pellencus.com

This site uses cookies. By continuing to browse the site, you are agreeing to our use of cookies.

AcceptLearn moreCookie and Privacy Settings

We may request cookies to be set on your device. We use cookies to let us know when you visit our websites, how you interact with us, to enrich your user experience, and to customize your relationship with our website.

Click on the different category headings to find out more. You can also change some of your preferences. Note that blocking some types of cookies may impact your experience on our websites and the services we are able to offer.

These cookies are strictly necessary to provide you with services available through our website and to use some of its features.

Because these cookies are strictly necessary to deliver the website, refuseing them will have impact how our site functions. You always can block or delete cookies by changing your browser settings and force blocking all cookies on this website. But this will always prompt you to accept/refuse cookies when revisiting our site.

We fully respect if you want to refuse cookies but to avoid asking you again and again kindly allow us to store a cookie for that. You are free to opt out any time or opt in for other cookies to get a better experience. If you refuse cookies we will remove all set cookies in our domain.

We provide you with a list of stored cookies on your computer in our domain so you can check what we stored. Due to security reasons we are not able to show or modify cookies from other domains. You can check these in your browser security settings.

These cookies collect information that is used either in aggregate form to help us understand how our website is being used or how effective our marketing campaigns are, or to help us customize our website and application for you in order to enhance your experience.

If you do not want that we track your visit to our site you can disable tracking in your browser here:

We also use different external services like Google Webfonts, Google Maps, and external Video providers. Since these providers may collect personal data like your IP address we allow you to block them here. Please be aware that this might heavily reduce the functionality and appearance of our site. Changes will take effect once you reload the page.

Google Webfont Settings:

Google Map Settings:

Google reCaptcha Settings:

Vimeo and Youtube video embeds:

The following cookies are also needed - You can choose if you want to allow them:

You can read about our cookies and privacy settings in detail on our Privacy Policy Page.

Privacy Policy